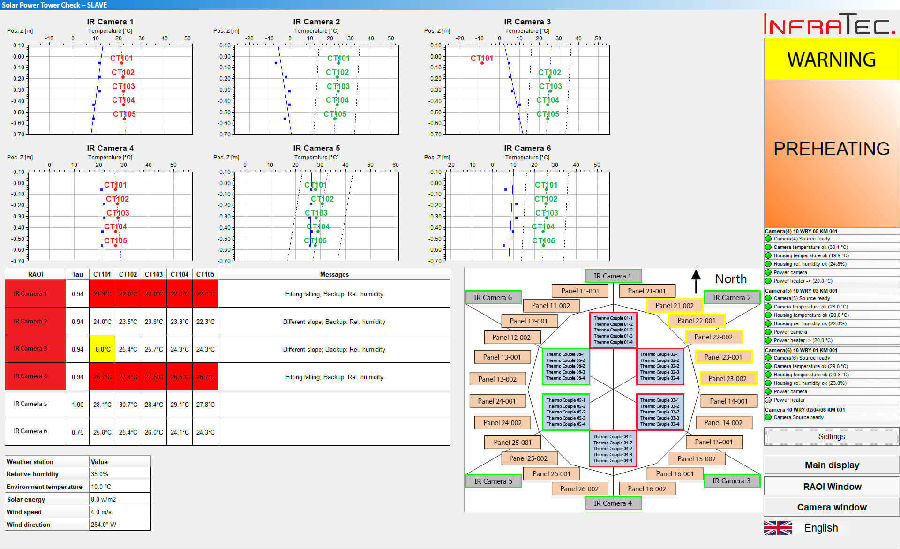

SPTC automatically raises warnings and alarms as soon as an adjustable temperature threshold is exceeded and transfers signals to the main system for controlling the deflection of heliostats. This enables the heat distribution at the absorber to be monitored and optimised. Due to the thermographic analysis of the surface of the absorber panels, any anomalies are detected at an early stage. This reduces maintenance costs and prevents cost-intensive downtimes due to overheating.

The turnkey solution for monitoring comes with highly reliable components in a flexible structure and thus, it is easily adaptable to the different situations and operational modes in solar power tower plants.

System Features

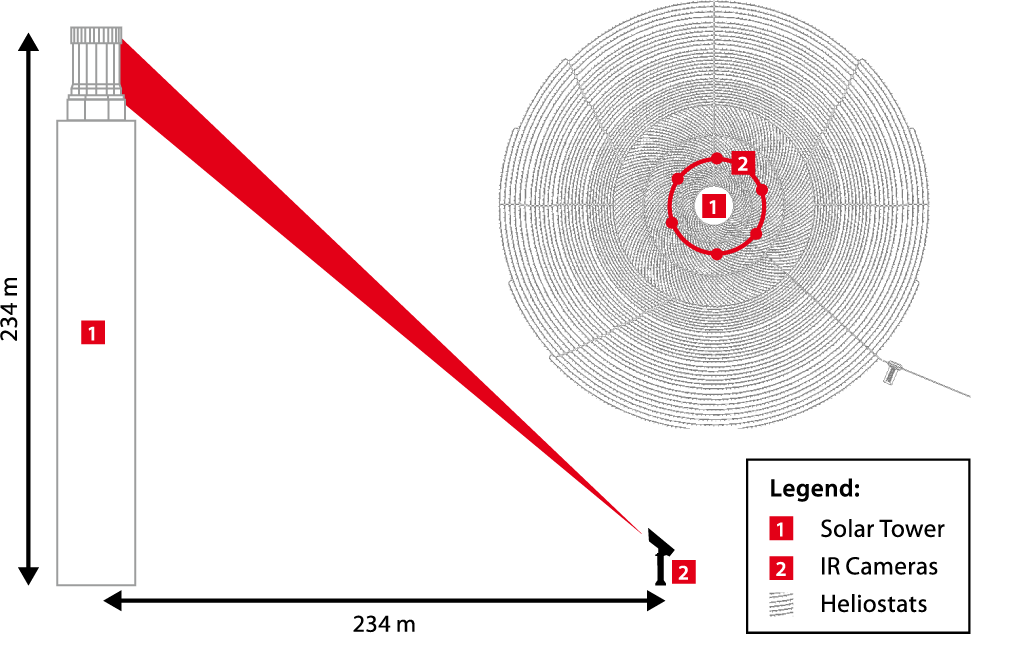

Position of IR cameras around the solar tower – measuring distance 330 m

- Multi camera system for fully 100% monitoring of absorber surface

- Highly detailed measurement of the panel temperature of the absorber

- Extensive conditioning of live images through automated focus tracking, size rectification and image stabilization

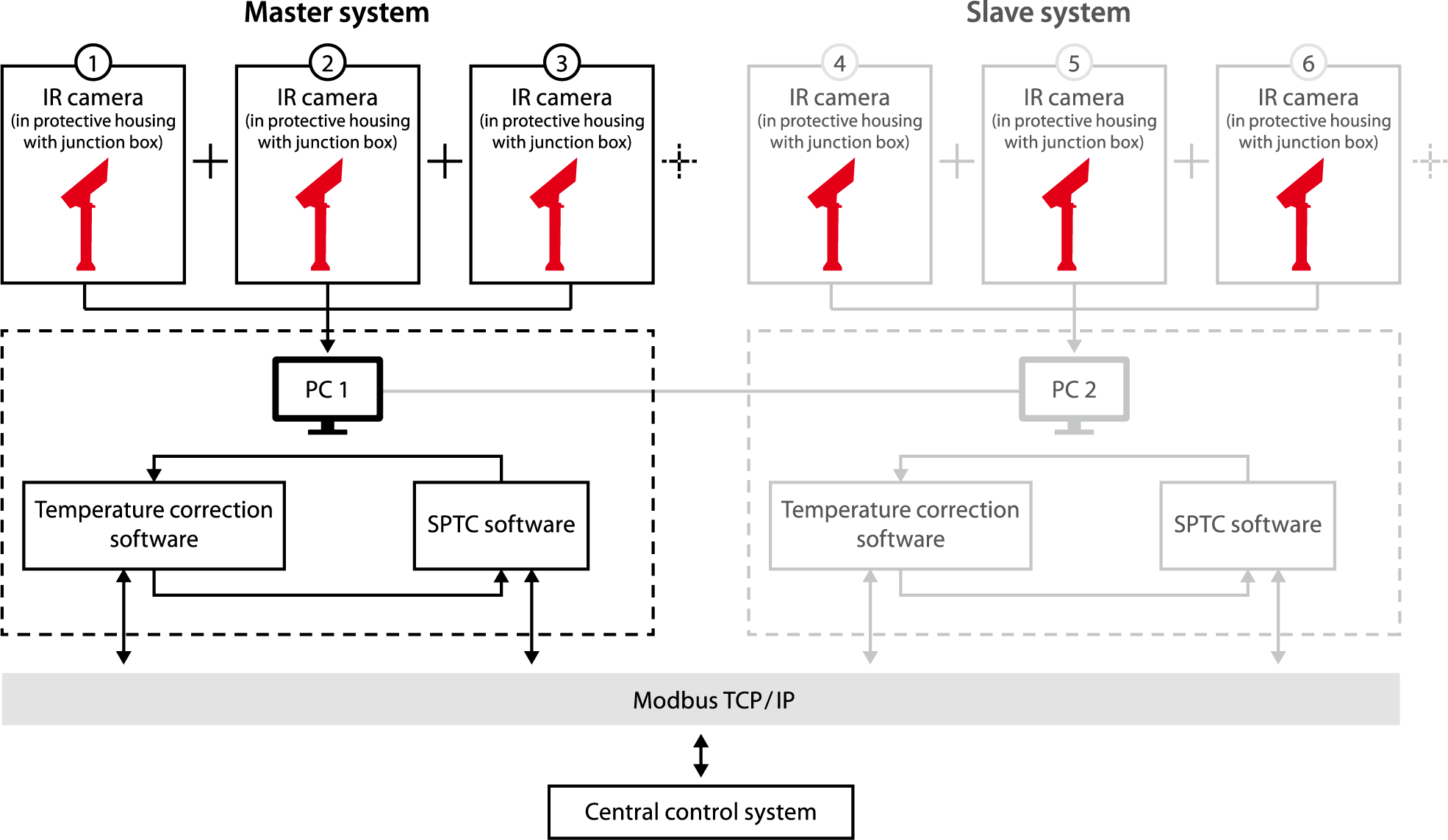

- Redundantly designed hardware and software for the entire system

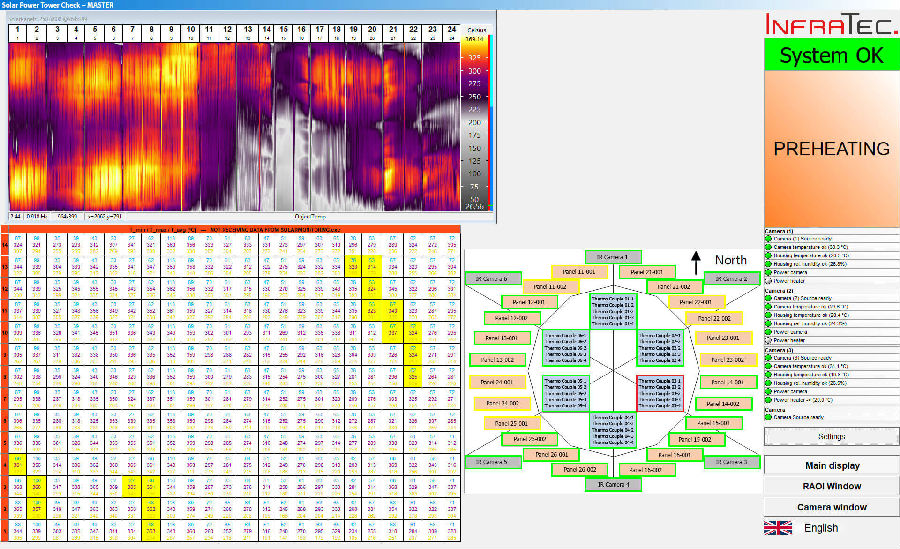

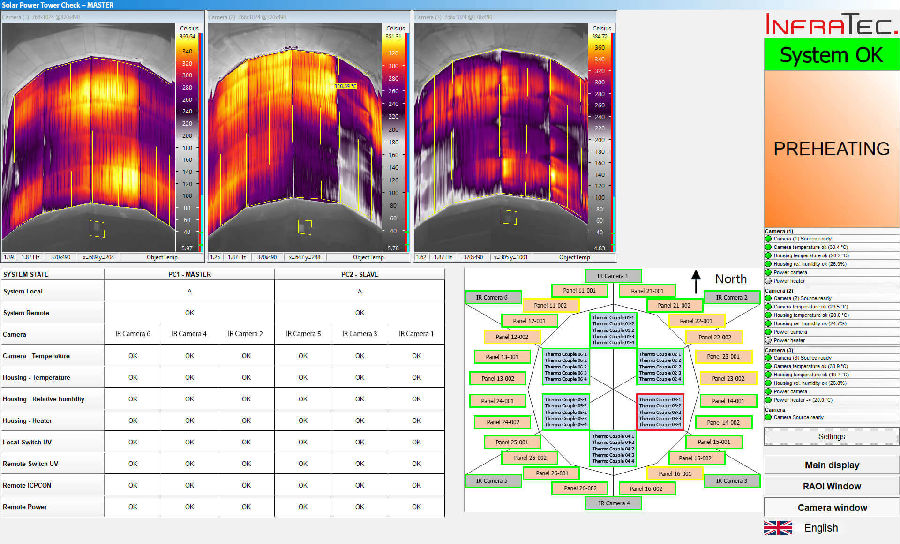

- Main display with options for parameter setting, monitoring, operation, display, evaluation & playback with SPTC software

- Clear graphics with temperature values of the entire absorber surface, warning or alarm values in a table

- Continuous and fast transfer of all temperature and system data to the central power plant control system

- Customised system alignment and adjustment

Benefits of the SPTC System

- Automatic and complete absorber temperature monitoring on 24/7 basis

- HD thermography cameras and optimised tele lenses guarantee long-term precise and reliable temperature measurements via long distance

- Reduction of maintenance costs and downtimes

- Continuous real-time measurement and temperature analysis

- Redundant design of the complete system for safe operation

- Specialised temperature measurement algorithm and software with interface to main operator system

- Optimised system for commissioning and regular operation of CSP solar power tower plants

System Structure of Hardware and Software Components

Components

HD thermography camera with special telephoto lens

- HD thermography cameras with highest resolution of (1,024 × 768) IR pixels

- Rugged 19″-industrial standard main cabinet

- Protective housing designed to withstand extreme environmental conditions

- Decentralised installable components (IR-cameras, PC, alarm unit), fiber optic cable for interference-free data transmission

- TCP / IP based flexible structure

- Highly redundant transmission adjustment based on different measurement methods

- Redundant power supply, data transmission, complete data exchange via master and slave PC

- Easy to use SPTC software allows flexible customisation

Composite thermal image of the measurement range of the absorber surface and display of the temperature values

Data analysis to align the transmission and evaluate the state of the associated components

Live view of IR cameras with status overview of redundant system components