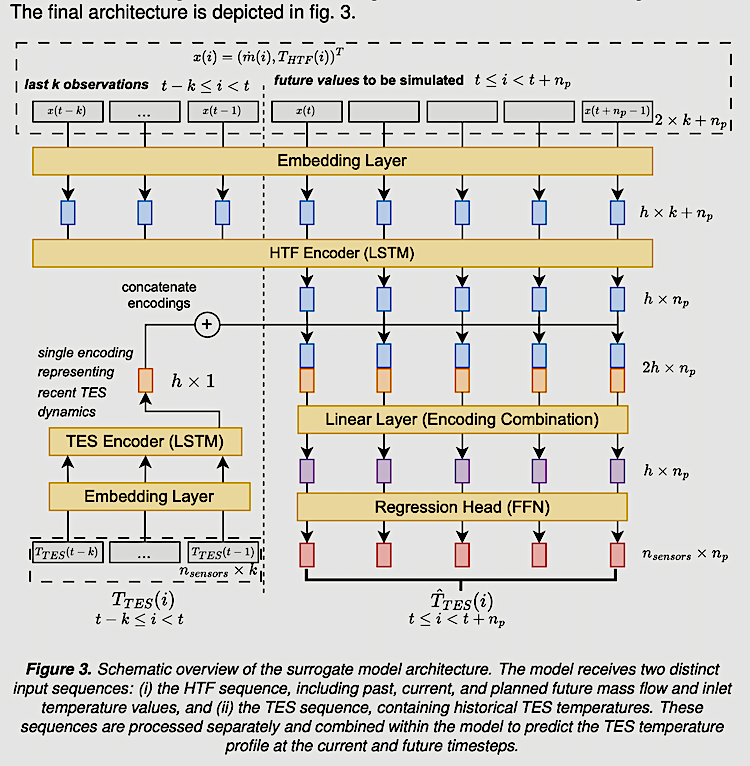

IMAGE °C Falko Scheider Schematic overview of the surrogate model architecture

Collaborating with Synhelion engineers, a solar research team at the Solar-Institute Jülich (SIJ) of FH Aachen presented two papers at SolarPACES 2025 assessing the accuracy and reliability of dynamic process models for a solar fuel production system. They used operating data from Synhelion’s DAWN pilot plant.

In Synhelion’s solar fuel plant, DAWN, concentrated solar power drives endothermic chemical reactions to convert biogenic methane, carbon dioxide, and steam into synthesis gas (syngas), which can then be processed into liquid hydrocarbon fuels, such as kerosene for aviation or gasoline.

Because the methane and carbon is derived from bio-waste rather than fossil fuels, and heat is generated from concentrated solar heat instead of burning fossil fuels, Synhelion is pioneering a sustainable drop-in replacement for today’s liquid fuels.

Synhelion’s DAWN pilot plant in Jülich (which can be toured at the next SolarPACES conference in the Fall of 2026) uses RED-certified sustainable biogenic waste as the methane and carbon source and has demonstrated the complete production chain under real solar operation conditions.

Synhelion’s solar-absorbing gas receiver is a unique design that is capable of extremely efficient conversion of solar irradiance from the heliostats to temperatures as high as 1500°C.

How can Synhelion’s solar receiver achieve such high temperatures?

Speed matters for real-time simulation

Now that Synhelion is beginning its first commercial production of solar fuels, plant operators will need to adapt to changing information in real time. Traditional physics-based models can be fast, but that usually comes at the cost of lower accuracy. So the team took a new approach.

“We needed a system where we can offer simulation results in real time to aid the operators who run the plant and make the decisions,” explained lead author Falko Schneider in a call from SIJ in Germany.

“For example, when to switch operation modes, what kind of mass flows or compositions of the reactants to set. To achieve this, we need models that can deliver both high accuracy and high computational speed. You can also use the process model offline to test potential operating and control strategies, of course, where speed doesn’t matter as much. The physics-based model takes a bit longer, but still, it’s very fast. It’s not like it needs days to simulate a week of operation.

The studies are to validate physics-based and machine-learning-based models for simulating DAWN’s solar fuel plant operation. The idea is to replace the more computationally expensive physics-based simulations with machine-learning models and validating an efficient alternative. The team first created a machine-learning model of the thermal energy storage with synthetic data from the physics-based model and successfully validated it.

In the overall system study, Validation of a Dynamic Process Model of a Thermochemical System for Solar Fuel Production, all three key components are validated against real-time operation. The key components are the solar receiver, the reforming reactor where the thermochemistry happens, and the thermal energy storage, which is crucial in solar fuels production, as the thermochemistry must operate continuously.

Synhelion’s high-temperature solid thermal energy storage system uses ceramic refractory bricks with internal channels to carry the heat transfer fluid.

The thermal energy storage had the most comprehensive study

The second study, A Validated Machine Learning Approach to Efficient Thermal Energy Storage Simulation Using Synthetic Data, focused on this component, the thermal energy storage. Of the three aspects studied, the thermal storage was most fully modeled.

The thermal energy storage model successfully reproduced charge-discharge transients over 8 cycles across 10 days, achieving errors of less than 3% of the temperature swing in the upper storage layers, although deviations increased toward the bottom due to potential material property variations and mass flow measurement uncertainties.

The team’s surrogate model yielded results in milliseconds on the synthetic validation data, compared with on average over five seconds for a physics-based model—making it roughly 100 to 1000 times faster. On operational validiation data from DAWN, it is even up to 50.000 times faster. Its run times were also much more consistent, allowing the system to run many simulations very quickly, making it practical for optimization tasks or real-time control.

Since solar flux onto the receiver wasn’t directly measured during operation, the researchers developed a simplified data-driven surrogate solar field model using a 4th-degree polynomial with ridge regression.

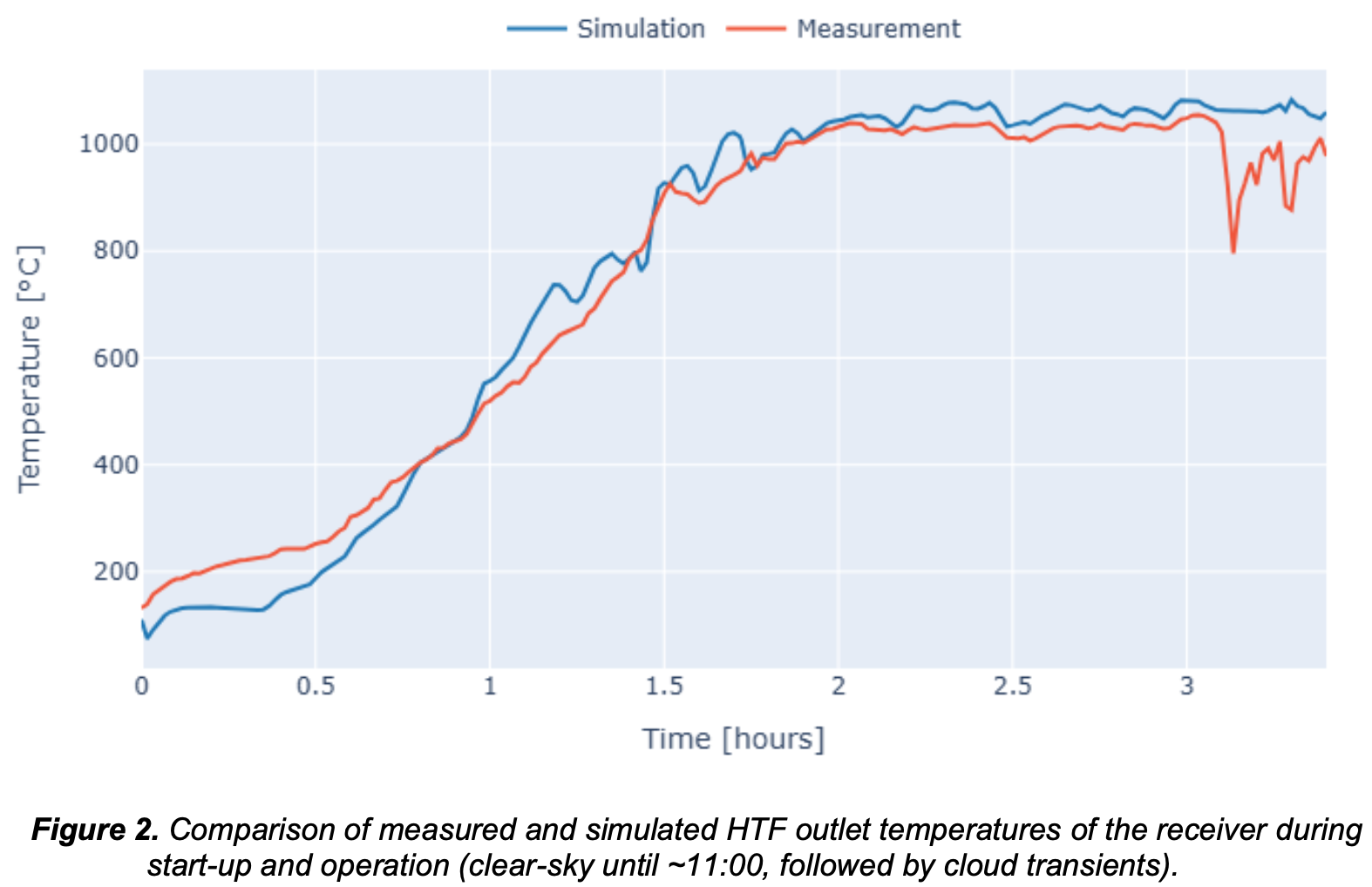

“We used experimental data as input and compared the output to the experimental data,” Falko explained. “ The coupled surrogate-receiver simulation achieved outlet gas temperatures of approximately 1000°C, showing good agreement with experimental data, although it slightly overestimated temperatures due to a minor systematic bias in the surrogate model. And since then, the receiver has been operated at output temperatures of over 1200°C.

The model validation for the reforming reactor revealed major discrepancies, though. Especially under partial-load conditions, the model overestimated the reaction rate and heat consumption, with residual methane present, contrary to equilibrium predictions, and lower CO₂ conversion than expected.

“We still have some work to do there,” Schneider noted.

“Usually you have these physical models, and then you fit them with operational data. There are components that work very well, right out of the box, without a fitting. The thermal storage model worked quite well already without any fitting. But regarding the chemistry, we need to do some more work. We assumed that a thermochemical equilibrium had been reached within the reactor. That was the statement we got from an industrial manufacturer. However, in the end, it did not align with reality, probably due to the relatively small reactor size.”

So the team needed to implement some kinetics:

“For example, we could implement some factors that allow us to say, ‘Okay, depending on how fast the reactants flow through the catalyst, it will get that close to a thermal chemical equilibrium.’ If it reaches or not, or how close it gets, and what the composition would look like are factors that can be fitted with operational data from DAWN. So this is about the reactor kinetics,” he said.

Work continues on the solar receiver and the reforming reactor

“For the solar receiver, the problem is that we do not have the operational measurements of the concentrated flux hitting it,” he said. “So we are missing an input variable, and we don’t have a detailed model of the heliostat field because a lot of factors go into this. You usually use ray tracing tools to create these kind of models which are not applicable in the process model. So I created this approximation of the heliostat field model, and used that to validate the receiver model. That’s not a strict validation, but at least it’s a successful plausibility check.”

And the reforming reactor model still needs major improvements. It may be necessary to replace the current equilibrium method with a kinetic model or utilize effectiveness factors to more accurately capture how the system behaves under partial loads. However, both provide a solid base for building a digital twin of the solar fuel process.

“Since we are already creating some component models based on machine-learning, we are checking as well if this would be suitable to accurately reproduce the chemistry,” Scheider pointed out.

“This was a publicly funded project between Synhelion, SIJ and Germany’s Institute of Future Fuels at DLR as partners, within which DAWN was built. DLR also created a small lab setup to evaluate different kinds of catalysts. They developed more detailed chemical models with that data. So we are working with them to see whether we can implement it in our model.”

The team’s machine-learning models have been developed within the TwinSF project in the EU, which combines tested physical models with data-driven approaches to help guide operations in alternative fuel production plants using concentrated solar energy to produce sustainable fuels.

The long-term goal is to develop a functioning digital twin that enables real-time plant monitoring, predictive control, and virtual testing of control strategies before they get implemented on an actual solar fuels plant’s system.

Synhelion has now delivered its first solar aviation fuel to SWISS

How Synhelion’s solar jet fuel started – an interview in 2017

The post Researchers create a digital twin to run DAWN, Synhelion’s solar fuels plant appeared first on SolarPACES.