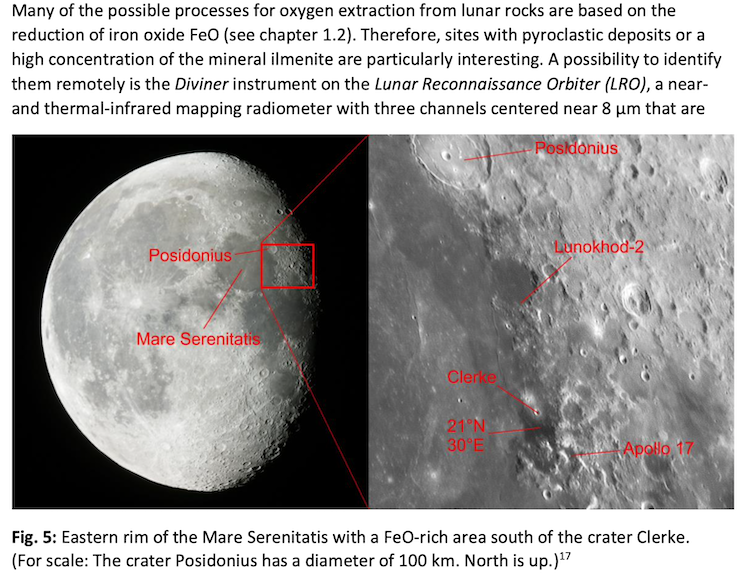

IMAGE from: Terrestrial Demonstrator for the Hydrogen Extraction of Oxygen from Lunar Regolith with Concentrated Solar Energy °C Thorsten Denk

Working at the Plataforma Solar de Almería (PSA), aerospace engineer Thorsten Denk has further refined his solar reactor for extracting lunar oxygen directly from ilmenite (FeTiO3), an abundant mineral in lunar regolith. Inspired by NASA’s call to extract oxygen from the Moon, Denk’s fluidized bed prototype has undergone several improvements since we first covered its early progress in 2017.

Concentrated solar energy is the heat source for a chemical reaction run at temperatures around 950°C. The latest solar tests of his reactor, a fluidized bed design, achieved close to 100% hydrogen conversion.

How fluidized bed solar reactors work

Fluidized bed reactors are used commercially in many chemical industries and have also now been extensively researched for solar thermochemistry applications, even on the Moon. Instead of using fossil fuels or electricity for heat, mirrors can reflect and concentrate the Moon’s 14-day sunlight hours, able to generate temperatures well above 1000°C.

Denk’s reactor has a large quartz window that allows concentrated solar rays to directly heat the lunar soil simulant (The scarce samples brought back by Apollo are too valuable to be used up in experiments. So researchers use a similar soil found on Earth for experimentation).

The heat is generated by a solar ‘furnace’, a pair of mirrors configured so that the first mirror is a heliostat that tracks the sun, and that in turn reflects the sunlight into the second one, which is curved in a parabolic shape to concentrate the solar flux into the reactor chamber.

The advantage of using concentrated solar energy is that it requires only mirrors to generate heat for the chemical reaction

The advantage of ilmenite is that it will react at temperatures as low as 950°C, so there’s no need to melt the material, greatly simplifying the complexity and the energy demand of the process. The advantage of fluidized beds is that they excel at mixing fine particles, such as ilmenite.

Denk explained in a call from Spain that in the fluidized bed, there is a very good contact between the gas and the solids, so there is a high probability for each molecule that the reaction will occur.

Pouring the ilmenite particles. IMAGE °C Thorsten Denk from Terrestrial Demonstrator for the Hydrogen Extraction of Oxygen from Lunar Regolith with Concentrated Solar Energy

“It’s like a pot where you have the particles inside and the gas passes slowly at the right velocity from bottom to top through the particles, so they are fluidized,” he said.

“At the bottom is the gas distributor, designed so that the gas can enter, but the particles are prevented from falling down. This concept is also used for the auxiliary piping, such as particles feed and removal. A funnel is positioned higher than the main reactor, so the difference in level enables the particles flow to occur. By adjusting the gas flow for fluidization of the so-called standpipe, I can also adjust the mass flow of particles. On the other side of the reactor, the particles flow out, also through a fluidized pipe to avoid the gas following the particles through the same pipe. The gas has to go out through a separate exit.”

How the solar-driven ilmenite chemical reaction works

The process extracts oxygen from ilmenite (FeTiO3), using hydrogen as a reducing agent at temperatures around 950°C, with water as the intermediate product.

The ilmenite is an iron-titanium oxide. To remove the oxygen, you add hydrogen and heat the material with solar, causing it to release water out of the first step:

FeTiO3 + H2 + solar heat → Fe + TiO2 + H2O

The second step is in an electrolyzer using the product water from the first step. (A PV panel could supply this electricity.) The water is split to produce hydrogen and oxygen:

H2O + electric power → H2 + ½O2

The oxygen is the product, and the hydrogen gets reused. (Hydrogen is the lightest element; a finite amount could be brought up from Earth, and it would be looped in the reaction, being reused over and over.)

The residence time of the ilmenite in the reactor is quite long, averaging up to an hour or more. Denk has been feeding 110 to 220 grams per minute of particles, each measuring about 150 micrometers, which then enter the reactor for the chemical reaction.

Why switch to argon as the fluidizing gas?

There are actually two different gases in the fluidized bed. Although hydrogen is the reactant in the reaction chamber, Denk switched to argon as the fluidizing gas to swirl the ilmenite particles around.

“People at PSA were afraid of working with pure hydrogen at this high temperature, because of the risk of explosions. But on the Moon, this is not a problem because there is no oxygen atmosphere, so there’s no danger of explosions. Up there, it would be easier to work with only hydrogen, using it both as the fluidizing gas and the reactant gas. The kinetics would be better,” he explained.

Experimental challenges of simulating lunar conditions

There are inevitable inaccuracies when working with any simulant. The one ton of ilmenite simulant from Madagascar used by Denk has impurities that it would not have on the Moon, for example. Insects have crawled through it, leaving tiny traces of carbon. There would not be any carbon in lunar ilmenite.

The difference in gravity also introduces uncertainty. Gravity influences the behavior of the fluidized bed. With only 1/6th of Earth’s gravity on the Moon, you wouldn’t need the same gas flow speed to fluidize the particles.

There are many unknowns, even the actual grain size distribution of the lunar material. If the ilmenite at the surface is too fine, like dust, that would not be optimal for fluidized bed reactors. However, Denk is betting that the grain size will turn out to be more gritty some centimeters below the surface, similar to the grain size he worked with, about 150 micrometers.

Final results

Over 150 hours of operation, including 21 hours using hydrogen, the system produced more than 1.3 liters of water: a direct measure of oxygen liberated from the regolith.

Denk’s results show that if the lunar regolith feedstock is as rich in ilmenite as early data suggests, then continuous, on-site lunar oxygen generation will be possible.

Scientist Devises a Solar Reactor to Make Water and Oxygen from Moon Rocks

Startup concentrates solar to melt NASA’s lunar landing pads

The post PSA advances a solar reactor to extract oxygen from lunar ilmenite appeared first on SolarPACES.