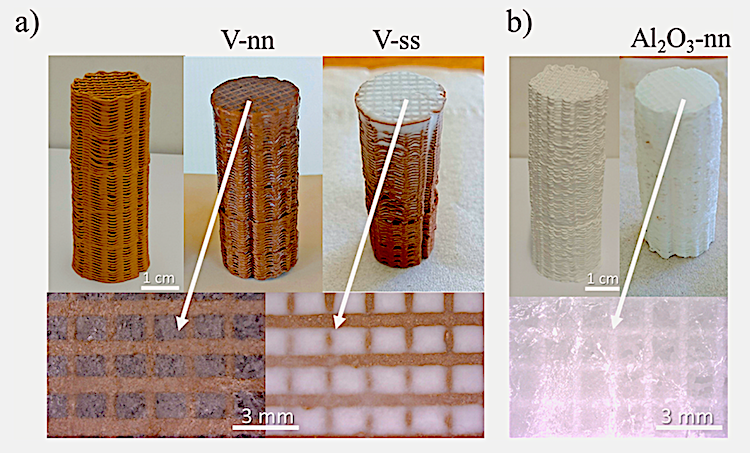

3D-printed vermiculite and alumina samples. IMAGE © Thermal energy storage behaviour of 3D ceramic:molten salt structures under real concentrated solar radiation.

Researchers collaborating between ICV-CSIC in Spain and at the Odeillo solar furnace in France have devised a novel way to maximize thermal energy storage in Concentrated Solar Power (CSP) plants.

They wanted to encapsulate the maximum amount of the molten salts used in CSP storage within a custom 3D-printed ceramic lattice. Their idea is to try out different less corrosive materials like ceramics and to increase their porosity by 3D-printing them to spec. The team has now tested a prototype on-sun to show that it worked.

The team tested two ceramics, vermiculite and alumina, infiltrated with two phas-changing materials (PCM), sodium nitrate (NaNO3) and solar salt, a mixture of sodium nitrate and potassium nitrate (KNO3), typically used in today’s Tower CSP. The ceramic parts infiltrated with molten salts exhibited good thermal energy storage performance while ensuring corrosion resistance.

These hot molten salts liquids reach temperatures of up to 565°C. They are typically stored in large metal tanks, supplying stored solar energy that powers the solar thermal power plant, enabling solar generation even after dark. But the molten salts are very corrosive to metals.

Why not insert a ceramic, and control its porosity by 3D-printing it?

The idea was to see if 3D-printing these ceramic materials – making them super-porous – could better work to contain the hot liquid in the thermal energy storage containers. They would need to see how well the extra porosity of these 3D-printed ceramics, which allow large amounts of PCM, enhances their ability to store and release heat under real solar conditions.

SolarPACES spoke with Irene Díaz-Herrezuelo, now a postdoctoral researcher at IMDEA, about their recently published findings, Thermal energy storage behaviour of 3D ceramic:molten salt structures under real concentrated solar radiation.

“This is the first time 3D printed ceramic structures infiltrated with the PCM have been tested under real concentrated solar radiation,” she noted.

“In the past, they validated foams and other composites, but not with 3D-printed materials combined with the molten salts in use today. So we are the first. The main goal is to avoid using metal containers for molten salts in thermal energy storage systems. Nitrate salts are very corrosive to metals. Using porous ceramics solves that problem, and they are also thermally and chemically stable. The high porosity of these ceramic structures allows them to hold a large volume of liquid salts and retain their heat during thermal cycling. The idea is that the salt inside the porous ceramic structure absorbs heat, and releases it when required, like when clouds pass, helping to provide a stable energy supply.”

Why test on-sun

Of course, the sun doesn’t shine down into the thermal energy storage tank where the porous structures would be.

How solar thermal energy storage works with concentrated solar

Still, the sun heats the liquid salts in the solar receiver on the tower, and when that heated liquid feeds down into the storage tank, the heat will be absorbed by the porous 3-D printed ceramic structure.

By doing the test in real sunlight, they can see how aspects like solar absorptance, thermal emittance, heat transfer, and energy conversion efficiency behave in realistic, dynamic environments, which you can’t get in lab bench tests under simulated sunlight. The on-sun test ensures the materials can withstand the real-time thermal cycling and solar flux expected in commercial CSP plants.

“We tested how the ceramic structures infiltrated with nitrate salts behaved under real solar radiation, how much these 3D-printed structures can absorb and release heat,” she said.

The advantage of 3D-printing the ceramics

These ceramics already have high thermal, corrosion, and mechanical resistance,” said Díaz-Herrezuelo.

“But with 3D printing techniques, we could precisely control the porosity, through the design of the cellular patterns, so that the salt is strongly retained, avoiding leakage to the surroundings. And also, 3D-printing cellular structures enables an increase in the heat transfer area to promote a more efficient heat transfer rate.”

Although they tested this for molten salts at the temperature used in today’s commercial Tower CSP, future plants may use even higher-temperature salts.

“We might explore this in future research,” she added.

“Carbonate salts like sodium or potassium carbonates can go to even higher temperatures, like up to 900°C so they have the potential to increase the energy density, so we would test these same 3D-printed ceramics, particularly the alumina materials because it has double the thermal conductivity of the vermiculite., and other ceramics had poor thermal conductivity, but I’d try infiltrating with different molten salts that would achieve higher temperatures.”

The setup

First, a 3D printer was used to create lightweight, lattice-type structures out of either vermiculite or alumina. After these supports were printed and sintered, they were filled with the melted salts. They tested their samples outdoors at one of the solar furnaces at PROMES in Odeillo, France, which can achieve temperatures exceeding 3,000°C. However, since they were only testing for the molten salts used commercially today, they only needed 14% of the power of the mid-size solar furnace there. This has a one and a half meter parabolic mirror and a maximum total power of 850 W at the focal point, assuming a DNI of about 1000 watts per square meter.

3D-printed ceramic prototypes in vermiculite and alumina IMAGE © Thermal energy storage behaviour of 3D ceramic:molten salt structures under real concentrated solar radiation.

Each test sample, 20 mm wide, was placed inside a protective stainless steel tube. They irradiated the top part of the specimen, ensuring the whole 3DTES top surface was irradiated. To spread the heat evenly, a metal (Inconel) black-painted lid with a special heat-absorbing coating (Pyromark) was placed on top.

They heated the top surface of the 3D-printed ceramic cylinder and analyzed how heat transferred through it while being irradiated by the concentrated sunlight. Then they stopped the solar input to observe how quickly it cooled down, and to study the rate of heat propagation.

What they found

All the samples effectively were able to melt both PCM contained in the ceramic structures. But each of the two 3D-printed ceramic materials revealed differing potential applications.

The vermiculite-based 3D-printed samples soaked up more salt (about 81% by weight) and absorbed sunlight best, converting nearly 67% of incoming solar energy into heat. Vermiculite with sodium nitrate stored about 10% more energy per unit mass than alumina with sodium nitrate.

Alumina-based structures didn’t hold as much salt (about 65% by weight). Still, with its higher thermal conductivity, alumina transferred heat almost twice as fast as vermiculite, making alumina ideal for fast energy cycling.

3D-printed ceria is a game-changer to increase solar fuel efficiency

A solar sulphur cycle to make unlimited thermal energy storage

The post 3D-printed ceramics tested to maximize thermal energy storage in molten salts appeared first on SolarPACES.