Source: Die Weltwoche

“The dream becomes reality”

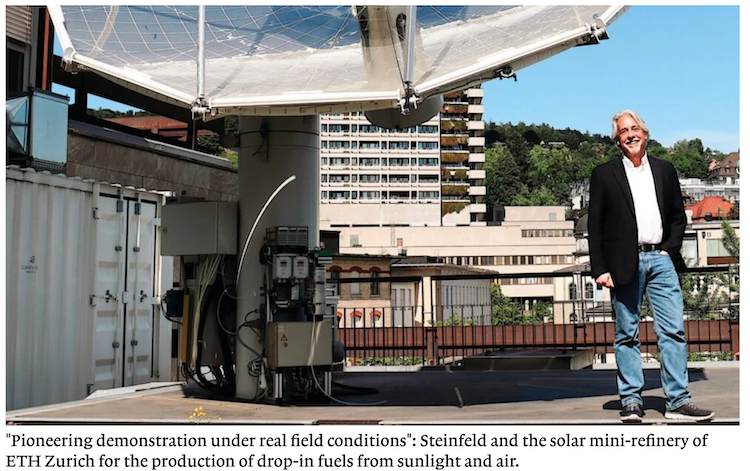

ETH professor Aldo Steinfeld is one of the pioneers of synthetic fuels. He explains how to capture the solar energy in such a way that it can be poured into the tank.

When will the synthetic fuels that can be handled and transported, like gasoline, diesel or kerosene, which are not of fossil origin, but are climate neutral? Such super remedies are vocational for the specifications in the car, transport and aviation industries. Do they come?

We ask an expert who is working on it: Aldo Steinfeld is a full professor of renewable energy sources at the Department of Mechanical and Process Engineering at ETH Zurich. He is a prominent researcher in the field of solar technology and solar fuels, combined with extensive publication activities, 27 patents and the supervision of sixty doctoral theses.

His research group Professorship of Renewable Energy Carriers (PREC) at ETH Zurich has developed technology innovations in solar energy conversion and produced two successful spin-offs: Climeworks and Synhelion. Climeworks is focused on the technology for CO2 capture from the air, Synhelion markets the technology for the production of solar fuels, as shown here on the previous pages.

Weltwoche: Professor Steinfeld, you have been seriously involved in the generation of solar fuels in your scientific career. How did you come to it? Was there a decisive experience that brought you on this path?

Aldo Steinfeld: Thank you for this question. As I closer to retirement at the end of the spring semester of this year, it is a good time to think about past experiences. It was an amazing journey. Since the beginning of my career, the production of solar fuels has been the most important part of my research. The motivation was clear: with only 0.1 percent of the Earth’s land area, one could collect more than enough solar energy to meet the energy demand of the world’s population. In addition, the solar energy supply is unlimited and its use is ecologically harmless. Reasons enough to expect a comprehensive use of solar energy, if there were not some very serious disadvantages, namely: the solar radiation that reaches the Earth is very thin, intermittent and unequally distributed. I wondered: How can we get a sunbeam so that it can be stored, transported and used to drive our cars, ships and planes?

Weltwoche: According to the motto: “Do the sun into the tank”?

Steinfeld: Yes, this question motivated me to look for recipes with which you can convert sunlight into storable chemical energy into the form of fuels. Airplanes flying with fuels made according to such a prescription would actually fly with solar energy, even if it is rainy night.

Weltwoche: For many, hydrogen is considered the fuel of the future. Does that be done to you?

Steinfeld: First of all, my focus was on the solar production of hydrogen from water for the purpose of decarbonising transport and other industrial sectors. However, in view of the challenges of storing, distributing and using H2 as a fuel for traffic, I have again focused my research on the solar production of so-called drop-in fuels from water and CO2.

Weltwoche: So almost what you can pour in canisters?

Steinfeld: Absolute, in the canister or directly in the tank. Drop-in fuels are synthetic, liquid hydrocarbons such as kerosene, gasoline or diesel that can use the existing extensive transport infrastructure for the storage, distribution and end use of fuels, and therefore do not require any new technologies beyond the production chain. Drop-in fuels can therefore easily replace fossil fuels, and solar kerosene in particular can make aviation more sustainable.

Weltwoche: How did you get to ETH in Switzerland?

Steinfeld: After my doctoral studies at the University of Minnesota in the USA and a postdoctoral research stay at the Weizmann Institute of Science in Israel, I joined the Paul Scherrer Institute, which belonged to the ETH Domain, PSI, in 1991, where I later worked as head of the laboratory for solar technology. It was a unique opportunity to participate in the development of a research group in the emerging and promising field of solar chemistry.In 1999, I was appointed Professor at ETH Zurich and gradually transferred my research from PSI to ETH Zu (ETH). My research programme at ETH for the last 25 years has been aimed at the further development of the chemical engineering sciences, which are applied to solar energy technologies.

Weltwoche: Did “Swiss” play a role in the selection of its research topics, or is the university a completely global institution?

Steinfeld: Both. My research was based on the most important challenges in the field of energy and the environment on a global level and in Switzerland.

Weltwoche: Many people imagine that in the future the transport sector can be used in the transport sector, as in petrol, diesel or kerosene today, simply with the advantage that these new substances do not damage the climate. A dream combination. What do you think of these hopes?

Steinfeld: My comment on this is that this dream combination, this dream, becomes a reality.In 2019, we demonstrated for the first time in the world the production of sustainable drop-in fuels from two ingredients: from sunlight and air. This pioneer demonstration was carried out under real field conditions in our solar mini-refinery plant on the roof of the ETH machine laboratory in Zurich. And in 2027, synhelion will operate a ten times larger solar refinery in Spain and ramp up commercial production capacity.

Weltwoche: A central step in the production of drop-in fuels is to remove hydrogen from the water, to use the H atoms to the H-atoms, then further steps are taken with the hydrogen. Can you briefly describe how the processes in your research projects are and what the resulting products are?

Steinfeld: The solar refinery for the production of drop-in fuels integrates in a row three thermochemical conversion units, which are shown in Figure 1 schematically and with some technical language: Station 1 is the direct air capture (DAC) unit, which includes CO2 and H2O from the ambient air. An alternative option to the DAC is the use of biogenic CO2 from biomass. Station 2 represents the solar redox unit (SR), which converts CO2 and H2O with concentrated solar energy into a desired mixture of CO and H2 (synthesis gas). Station 3 shows the gas-to-liquid (GTL) unit, which converts synthesis gas into liquid hydrocarbon products such as kerosene, gasoline, diesel or methanol. These are the drop-in fuels that are ready for use in the existing global transport infrastructure.

Weltwoche: And these are climate neutral?

Steinfeld: Yes, these are CO2-neutral fuels because solar energy is used for their production and only as much CO2 is released during their combustion as has been taken from the air for their production. The life cycle assessment of the production chain for solar kerosene shows a avoidance of 80 percent of greenhouse gas emissions, based on fossil kerosene, and an approximation of zero emissions when building materials such as steel and glass for the heliostat field are produced with renewable energy.

Weltwoche: Does your plants work, put together in a simplified way, so that solar energy is directed and concentrated over mirrors on a certain point, where it is very hot, and that this heating leads the important chemical reactions?

Steinfeld: Correct. The solar refinery from Synhelion in Jülich, a field of sun-going parabolic mirrors, called heliostats, bundles the incident sunlight into a solar receiver mounted on a tower [see picture at the top left]. In this solar receiver, the concentrated solar radiation is efficiently absorbed and converted into heat of over 1200 degrees Celsius, which in turn is released to the chemical reactor for the thermochemical production of fuels. This route to solar fuels uses the entire solar spectrum and thus offers potentially high production rates and efficiency.

“Ready for use in the existing global transport infrastructure.”

“Ready for use in the existing global transport infrastructure.”

Weltwoche: How close are the plants that your scientists model are they from practical maturity? Is the start-up Synhelion a typical example?

Steinfeld: Yes, the systems are approaching technical maturity. In fact, Synhelion has commissioned Synhelion’s first solar refinery, called “dawn”, to demonstrate the robustness of the technology. In 2027, Synhelion is operating a ten times larger solar refinery called “Rise” in Spain with a thousand tons of solar energy. Commercial production capacity is being ramped up with the aim of producing one million tons per year by 2033 and covering about half of the European demand for Sustainable Aviation Fuel, called SAF, by 2040.

Weltwoche: Which drop-in products would be well suited in aviation, shipping, commercial vehicles, cars, stationary stores?

Steinfeld: Drop-in fuels such as synthetic petrol and diesel are fully compatible with the internal combustion engines of passenger cars, trucks and maritime shipping, while synthetic kerosene is fully compatible with jet engines of aircraft. It is important to note that these drop-in fuels, when produced by solar energy and CO2 from the air or from a biogenic source, are sustainable fuels.

Weltwoche: Which of these connections are the easiest in practical application?

Steinfeld: As already mentioned, all these drop-in fuels can use the existing transport infrastructure for storage, distribution and final consumption and therefore do not require new technologies outside the production chain. This means that drop-in fuels can replace fossil fuels or be mixed with you. Due to the challenge of decarbonising aviation, solar kerosene is the most attractive as a SAF.

Weltwoche: The production of drop-in fuels with solar energy is more expensive than that of fossil fuels. Which factors are decisive for this cost disadvantage? Can this disadvantage be compensated by the benefits of solar fuels? In which constellations would this be possible?

Steinfeld: Techno-economic analyses of the entire process chain, which are described in Figure 1, estimated the costs of solar kerosene in the range of one to two euros per litre in the long term. These cost values are mainly dependent on the energy policies of the solar redox unit, the CO2 costs by DAC or biomass processing and the production costs of the heliostat field, which are shown in Figure 1.

Weltwoche: But for the time being the cost difference is much higher?

Steinfeld: For the time being yes, but it will come down, first through scaling effects and process optimizations, and then through mass production of key components and learning by doing. I believe that the most appropriate instrument for bringing solar fuels to market would be a quota system that obliges airlines to introduce a minimum share of SAF in their total kerosene volume. This quota would initially be small and would rise every year, leading to new solar refineries and thus to falling costs, as we observed in photovoltaics. For example, the EU has already adopted a plan that envisages introducing a quota of 2 percent SAF this year, which is to rise to 2035 to 20 percent and to 70 percent by 2050.

Weltwoche: Are you optimistic about the future?

Steinfeld: Certainly. The technologies developed in our laboratories at ETH can be scaled to competitive costs and on a global scale, thus contributing to the decarbonisation of the aviation sector.

The post “Solar energy that can be poured in a tank”: the Aldo Steinfeld Weltwoche interview appeared first on SolarPACES.