Integration concept of energy resources can complement between the competing energy technologies. This manuscript presents a comprehensive review on the state-of-the-art of concentrated solar power (CSP) integration technology with various energy sources. Compared to CSP alone, integration of CSP and fossil fuel provides promising solution to solar energy intermittence, emissions and installation cost reduction, with 25% increase in electric power generation. On the other hand, integration of CSP with other sources such as geothermal and biomass can supply dispatchable power with almost zero emissions. The electricity produced via integrated CSP and photovoltaic (PV) has better power quality and less cost compared to that produced by PV alone or CSP alone, respectively. Integration of CSP and wind energy can meet peak demand, reduce power fluctuation and provide electrical power at a high capacity factor. However, the lack of reliable biomass, geothermal and wind data with the solar availability at specific locations is the main obstacle for the acceptance and further deployment of hybridization systems. The advantages and limitations of the hybrid technologies presented in this paper according to the literature are reviewed. Moreover, future directions of CSP such as production of hydrogen, solid particles receivers and the integration of supercritical carbon dioxide cycle are also discussed.

Integration concept of energy resources can complement between the competing energy technologies. This manuscript presents a comprehensive review on the state-of-the-art of concentrated solar power (CSP) integration technology with various energy sources. Compared to CSP alone, integration of CSP and fossil fuel provides promising solution to solar energy intermittence, emissions and installation cost reduction, with 25% increase in electric power generation. On the other hand, integration of CSP with other sources such as geothermal and biomass can supply dispatchable power with almost zero emissions. The electricity produced via integrated CSP and photovoltaic (PV) has better power quality and less cost compared to that produced by PV alone or CSP alone, respectively. Integration of CSP and wind energy can meet peak demand, reduce power fluctuation and provide electrical power at a high capacity factor. However, the lack of reliable biomass, geothermal and wind data with the solar availability at specific locations is the main obstacle for the acceptance and further deployment of hybridization systems. The advantages and limitations of the hybrid technologies presented in this paper according to the literature are reviewed. Moreover, future directions of CSP such as production of hydrogen, solid particles receivers and the integration of supercritical carbon dioxide cycle are also discussed.

Global energy demand is growing continuously in all sectors of life; consequently, fossil fuel consumption and atmospheric emissions are increasing. This is driving most governments worldwide to encourage the use of renewable energy resources in order to eliminate undesired environmental impacts. Although the share of renewables in global electricity generation reached 26% in 2018, renewable power as a whole still needs to expand significantly to meet the sustainable development scenario by 2030 [1]. As a consequence, there has been a significant increase in the use of renewable energy and in the number of countries and companies that adopted the commitment to a target of 100% renewable energy [2]. Solar energy is one of the main renewable energy resources with various advantages such as abundance and environmentally friendly. Compared to wind energy, solar energy has less or no moving parts and results in lower risk of damage, less maintenance requirements with greater reliability, silent operation, fast installation and close to 25-year warranty. On the other hand, providing dispatchable solar power presents a serious challenge due to the intermittent energy source. Therefore, solar energy requires an energy storage solution, or the integration with other system to supply dispatchable power [3]. Solar energy can directly be converted into electricity through photovoltaics (PV), or into thermal energy through different solar collectors and concentrators. Although PV is a promising solution for direct electricity generation, especially with the significant reduction in its price, the problems associated with the storage of the generated electricity are the main obstacles facing their widespread use [4]. Thus, the adoption of PV without storage may lead to grid reliability issues.

Concentrated solar power (CSP) uses the concentrated solar energy to heat up a heat transfer fluid (HTF). This thermal energy is converted into electricity through a thermodynamic cycle. CSP has attracted attention in the past two decades especially in countries with high direct normal irradiance (DNI) levels (>2000 kWh/m2/year). The conversion of solar energy into thermal heat through CSP enables the use of thermal energy storage (TES) in solar power plants [5, 6]. This offers CSP a unique advantage as a renewable energy source, since it has the ability to incorporate a TES. Moreover, CSP has the flexibility to integrate with other power plant systems [7]. The CSP integration can complement between the competing energy technologies in ways that are synergistic in terms of (i) reduction in capital cost, (ii) providing dispatchability, (iii) reliability, (iv) flexible operation and (v) more utilization of power generation equipment. CSP integration synergies are classified into light, medium and strong according to the equipment and solar share [8]. In light synergies, each energy source can operate independently without the other; the integration acts to fill the gap between the generated electricity and the utility electrical loading, such as integrated CSP-PV and CSP-wind energy [9, 10]. In medium synergies, the major equipment, i.e. steam turbine and condenser, are physically shared; this results in a significant reduction in the investment cost. However, the CSP cannot generate electrical power independently without the second plant (coal or natural gas power plant) [11, 12]. In strong collaborations, the major elements are shared as in the medium option but the CSP system can generate the required electric power due to the high solar share.

Geothermal and biomass are two types of renewable energy that convert thermal heat into electrical power as in CSP technology. Accordingly, they are more compatible for integration and commonly integrated for strong collaborations [13, 14]. Integration of these renewable energy sources provides 100% clean energy as well as can reduce capital costs through equipment sharing. Moreover, it can increase dispatchability, reliability and the capacity utilization of generation equipment and provide a flexible operation [15]. Wind power is considered as one of the fastest-growing renewable energy technologies. The global installed wind-generation capacity has increased by ~75% from 1997 to 2018 according to IRENA’s latest data [16]. However, the power output from wind is variable due to wind speed variation, which results in grid discontinuity. Considering that CSP with a thermal storage system can maintain continuous power supply as well as flexibility of the grid [17]. Integration of CSP with wind energy combines the low cost of electricity generation of wind and the relatively cheap TES option by CSP plants.

Several reviews have been carried out to summarize the progress made in CSP technology and design [18–22], including global progress and potential use [23], types of HTF [24] and progress in TES for CSP [5, 25, 26], and suggested thermodynamic power cycles for electricity generation using CSP [27]. However, few reports have been published covering the integration of CSP with fossil fuel and renewable energy sources. The main objective of this review is to discuss technically and economically the state-of-the-art integration categories used to integrate CSP with conventional and renewable energy resources, emphasizing on the configurations, capabilities and attributes. This work presents a comprehensive review on the state-of-the art of CSP integration technology with various energy sources and highlights different configuration for integration, advantage and disadvantage of each integrated system. Moreover, the review discusses on the limitations and challenges for CSP integration along with recommendations. Finally, future direction of CSP such as production of hydrogen, solid particles receivers and the integration of supercritical carbon dioxide cycle are presented.

2. Overview of CSP

CSP technologies have gained attention due to their ability to concentrate solar radiation and convert it into thermal heat. The collected thermal heat is used to create steam for electrical generation or industrial processing. The main four categories of CSP are divided according to sun’s rays focusing method and are the parabolic trough (PT), linear Fresnel reflector (LFR), parabolic dish and central solar receiver, as shown in Figure 1. PT solar collectors and central solar receiver are the most widely used commercial CSP technologies because of their lower operating costs and efficiencies that can exceed 70% at high temperatures [28, 29]. PT, the earliest CSP technology in use, is a line focus technology, which uses parabolic reflectors to concentrate the direct radiation on a receiver pipe. The receiver pipe, positioned on the focal line, heats the HTF from 290°C up to 550°C depending on the type of HTF [30]. The collected thermal energy in the HTF is then transferred to a thermodynamic cycle to generate electricity in a conventional steam generator. The receiver comprises a metal tube coated with selective layers to maximize absorbed solar radiation and placed inside an evacuated glass to minimize heat losses [31]. Synthetic thermal oil is commonly used as HTF, whereas other HTFs such as water/steam, molten salts and pressurized gases are currently being developed [32]. To maximize the optical efficiency of the PT, a one-axis tracking system is used. These collectors are also used for various applications such as domestic water heating and space heating, industrial process heat and desalination [33, 34]. LFR, similar to PT, uses fixed segmented mirrors, placed flat on the ground to reflect incident solar radiation towards the linear receiver located above the reflectors [35].

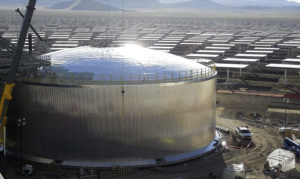

The central solar receiver (also called central tower) is one of the fastest-growing CSP technology. The first commercial-scale solar tower systems with a heliostat field and a central receivers have been commissioned and are operating successfully [36, 37], whereas other plants are in the process of being commissioned [38]. The solar tower system uses double axis tracking mirrors (heliostat) to concentrate solar radiation onto a fixed receiver placed at the top of a tower and to heat the HTF. Due to its high concentration ratio, the central tower can heat the HTF up to ~1000°C [39]. Early solar tower plants used steam as HTF, but recent designs use molten salt because of its energy storage ability or air because of its high operating temperature and availability [40]. The performance of central receivers is expected to improve mainly due to the research efforts devoted to (i) improve thermo-hydraulic design that allows higher solar flux as well as higher HTF outlet temperatures and (ii) use innovative selective coatings [38].

Reduced solar radiation in early morning and at night causes intermittence of the power provided by CSP. To eliminate this problem, studies have been conducted to develop efficient TES technology that can be incorporated with CSP [17]. Thus, CSP has a distinguish feature as a renewable energy source due to the capability to incorporate storage system. Moreover, it is an ideal technology to integrate with both conventional and non-conventional energy power plants. The shortage in power supply from CSP due to solar energy intermittence can be overcome by CSP hybridization. CSP shares technology with conventional power plants and can be fitted with other energy sources into a synergistic system. This leads to several benefits such as dispatchability, reliability, cost reduction and enhanced efficiency. The following sections describe the integration of CSP with different energy sources including fossil fuels, geothermal, biomass, solar (PV) and wind resources, highlighting integration configuration, capabilities and attributes.

3. Integration of CSP with conventional plants

Conventional power plants or fossil fuel power plants use coal and/or natural gas to supply electrical power. Both CSP and fossil fuel plants convert thermal energy to electrical power through the Rankine cycle or gas turbine. Integration of CSP with fossil fuels promotes the concept of using renewable energy, enhances the reliability on solar energy and reduces the associated cost. One possible cost-effective technique to develop integrated CSP-fossil fuel plant is to add the output from the solar field to an existing power plant [41]. Integrated CSP-fossil fuel power plants can be classified as thermal or thermochemical saturated or superheated steam. In the thermochemical integration, heat from solar energy is used for upgrading or decarbonizing the fossil fuel, which utilized as chemical reactants clean fuel generation [42]. There are several possibilities to integrate CSP with fossil fuel; however, this review is focused on integrated technologies commercially available rather than other emerging technologies such as hybridizing for oxygen production [43] or with chemical looping combustion [44]. Some of these new technologies have been reviewed recently by Nathan et al. [45]. Therefore, the following sections present the different configurations of integrated CSP with coal and natural gas power plants, the existing integrated power plants worldwide, as well as the advantages and limitation of the integrated system.

3.1. CSP-coal plants

Coal is a low-cost energy source; however, the combustion of coal increases the quantities of pollutants that affect negatively on the air quality and results in health problems and climate change [46]. The integration of CSP into the coal-powered plants reduces the pollutant effect and the operational costs. CSP and coal plants are classified as true hybrids power plants, since they usually showed a synergistic system during operation. During daylight, when solar radiation is available, energy can be harnessed by CSP that reduces coal combustion and CO2 emissions. When solar radiation decreases, the energy is harnessed from coal. The output from solar power in the hybrid CSP-coal plants can be in the form of solar steam generation, feed water preheating, air preheating, gasification and CO2 capture depending on the size and CSP technology.

A number of projects combining CSP and coal have been investigated worldwide, in USA, Europe, Australia, South Africa, China and the Middle East. These projects have demonstrated the benefits of power plant integration in terms of reliability, meeting renewable energy target, less consumption of fossil fuels and reduction of air pollution [47, 48]. Colorado Integrated Solar Project (CISP) was the first integrated CSP-coal project [48]. CISP was put into operation as a pilot-demonstration project for 7 months in 2010, to demonstrate the potential of CSP integration with large-scale coal power plants. PT integrated into 49 MW coal-fired power plant, to increase the plant efficiency and reduce the coal consumption, which led to a reduction in conventional plant emissions and CO2 [48]. The Electric Power Research Institute also hosted a demonstration project at a Pulverized Coal Plant, to integrate a 36 MW solar concentrator field into 245 MW Escalante Generating Station in New Mexico [49].

An investigation of CSP potential in Australia showed the technical feasibility of adding >15 GW of CSP capacity with minor grid extensions [50]. Consequently, Australian utilities showed an interest in coal–solar hybrids, but due to several limitations including low coal cost, the remaining lifespan of power plants and technical and commissioning issues, the integration of CSP and coal plants in several projects in Australia have failed [48, 50]. CSP-coal integration has been also suggested as part of the development solar thermal power generation strategy in China [51]. China has abundant of solar energy and unused land resources; on the other hand, it has serious air pollution problems. Therefore, several studies have been carried out to investigate the potential of integrating CSP into existing coal power plants. One of the studies evaluated the effect of using CSP to generate steam as boiler feed-water to 330 MW hybrid power plant in Changji City [52]. The study showed that, beside the reduction in gas emission, the electricity generated by integrated CSP-coal could be 20–30% cheaper than standalone CSP power plant. More integrated coal-CSP projects worldwide are listed in Table 1.

Table 1

Worldwide integrated CSP–coal power plants.

| Project | CSP technology | Solar capacity (MW) | Fossil plant/capacity (MW) | Remarks | Status | Ref. |

|---|---|---|---|---|---|---|

| CISP (USA) | Parabolic trough | 1 | 49 | Overall efficiency increased by >1%. Reduction in coal consumption and gas emissions (~600 t CO2, >900 kg NOx, and 2450 kg SO2) | It was in operation in 2010 for 7 months, as a demonstration plant | [55] and [48] |

| Escalante Plant (New Mexico) | Parabolic trough | 36 | ~220 | — | Project scheduled to start in 2011 but did not proceed | [56] and [57] |

| Sundt Solar Boost (USA) | Linear Fresnel | 5 | 156 | CSP added to conventional dual thermal power plant to produce 5 MW, with zero emission. Benefits included ~3600 t/year and ~8500 t/year reduction in coal and CO2 emission, respectively | Construction started in April 2014 and did not proceed | [58, 59] |

| Kogan Creek Plant (Australia) | Linear Fresnel | 44 | 750 | CO2 emission reduction estimated by ~35 600 t/year | Abandoned in 2016 due to technical issues | [55, 60] and [57] |

| Liddell Power Station | Linear Fresnel | 9 | 2000 | Reduction in coal consumption. Consequently, ~5000 t/year reduction in CO2 emissions | Operated in 2013 and closed in 2016 | [61] and [48] |

| Mejillone Power Plant (Chile) | Not mentioned | 5 | 150 | 1.5% of plant overall output expected to be supplied by solar power plant, efficiency expected to increase by 1% and coal consumption will be expected to reduce by 20 kt/year | No details have been made public | [55] and [57] |

| Bitola Power Station (Macedonia) | Not mentioned | 50 | 225 | Expected to reduce the amount of burned lignite and improve energy security | Feasibility study carried out as a part of Macedonia energy strategy 2013–2017 | [62] |

| China Huadian Corporation (China) | Parabolic trough | 10 | 200 | First solar–coal hybrid power plant in the Inner Mongolia Region | Under development | [45, 63] |

In addition to the reduction in coal combustion and CO2 emissions, the integration of CSP with coal reduces the total investment cost because of the sharing of main components. Many researchers have been interested to study integrated CSP-coal power plant. In a numerical study performed regarding the integration of a fossil fuel plant with a CSP plant it was estimated that the integrated power plant can cost 72% of the overall CSP cost [49]. Moreover, in the study, it was obtained that electricity power generation can be increased up to 25% [53]. Many researchers were interested to study integrated CSP-coal power plant. Zhang et al. [54] investigated two suggested arrangements to integrate solar tower with coal power plant. In the first scheme the solar tower was used in parallel with a coal-fired boiler to heat superheated steam, whereas in the second scheme the solar tower was used to heat sub-cooled feed water using a molten salt heat exchanger with a flue gas bypass in the boilers. With a solar contribution of 6.11% to heat the superheated steam, the efficiency of the integrated CSP-coal plant was 6.1% higher than the commercial solar plant PS10. With a 4.9% solar contribution to heat the sub-cooled water, the efficiency of the integrated CSP-coal plant was 3.6% higher than that of PS10.

Hong et al. [64] derived theoretical calculations of solar power efficiency, including exergy destruction of solar integration. They applied the derived equations into an existing integrated 330 MW coal-fired power plant to evaluate the thermal performance of converting solar energy to power. The solar energy was used to collect heat at 300°C by PT collectors, to preheat feed water instead of bleed steam from the high-pressure turbine. The study showed that the amount of output work for integrated power plant was increased compared with the coal-fired power system. Moreover, it was shown that at a given turbine load the solar-to-power performance was influenced by the solar irradiation and the incident angle. In other words, as solar irradiance increased, the heat collected by PT collectors can be used to replace the bleed steam for feed water preheating. This increased the net solar-to-power efficiency. On the other hand, at very high solar irradiance, the heat collected by PT collectors becomes more than that of the need for the feed-water preheated, which has a negative impact on the efficiency of the solar collector field [64]. Further studies with different configurations to integrate different CSP technologies with coal power plant are listed in Table 2.

Table 2

CSP-coal power plant configurations.

| Configuration | CSP heat transfer fluid temperature (°C) | CSP technology | Heat transfer fluid | Energy storage system | Solar-to-electricity efficiency | Ref. |

|---|---|---|---|---|---|---|

| Solar steam generation | 500 565 |

Linear Fresnel Solar tower |

DSG | Not mentioned | 38% to 45% | [65] |

| 570 | Solar tower | Molten salt | Two tank molten salt is used | 27.8% | [54] | |

| Feedwater preheating | 140 | Evacuated tube | — | Not mentioned | 11.4% | [66] |

| 282 | Parabolic trough | Thermal oil | Not mentioned | 24.1% | [66] | |

| 260 | Parabolic trough | Thermal oil | Not mentioned | 40.3% | [67] | |

| 267 | Parabolic trough | Therminol VPI | Not mentioned | 21.2% | [68] | |

| 283 | Parabolic trough | Thermal oil | 6 hours two tank molten salt | 21% | [69] | |

| 387 | Parabolic trough | Thermal oil | Not mentioned | 13.6 | [70] | |

| 398 | Parabolic trough | DSG | Not mentioned | 28.5% | [71] | |

| Air preheating | 540 | Solar tower | Air and solid particles | Hot particles used as storage medium | 22.3% | [72] |

| Gasification | 142.9 | Parabolic trough | DSG | Not mentioned | — | [73] |

| 650 | Solar tower | Molten salt | Not mentioned | — | [74] | |

| 1077 | Solar tower | DSG | Not mentioned | — | [75] | |

| CO2 capture | 295 | Parabolic trough | Therminol VP1 | Not mentioned | 27% | [76] |

3.2. CSP-natural gas power plant

Natural gas power plants have significantly lower CO2 emissions compared to that of coal power plants, since the burning efficiency of the gas is higher than that of solid coal [77]. Simple cycle gas plants and combined cycle gas plants (CCGT) are the two types of natural gas power plants [78–80]. In the case of hybrid CSP-natural gas power plants, integration can be directed to the steam cycle (SC) or gas turbine (GT). Therefore, solar energy through CSP is used to either boil water in the heat recovery steam-generator (HRSG) and then inject it into the high-pressure drum/steam turbine or heat the air leaving the compressor before combustion. The configuration of the two options is shown in Figure 2. Most of the existing hybrid CSP worldwide in USA, Mexico, Italy, Morocco, Algeria, Iran and Egypt are integrated with CCGT for supplying additional saturated steam to HRSG through a high-pressure drum [81]. Examples of worldwide-integrated CSP-natural gas power plant are listed in Table 3.

Integrated CSP-natural gas configurations: (a) solar energy used to superheat high-pressure water; (b) solar energy used to preheat the air leaving from the compressor before entering the combustion chamber.

Table 3

Worldwide integrated CSP—natural gas power plants.

| Project | CSP technology | Solar capacity (MW) | Fossil plant/capacity (MW) | Remarks | Status | Ref. |

|---|---|---|---|---|---|---|

| Martin Next-Generation Solar Energy Center (USA) | Parabolic trough | 75 | 1150 | Expected to reduce natural gas consumption and save ~$178 million in fuel cost, with a reduction of 2.75 × 106 t of CO2 emissions over 30 years | Operational since 2011 | [87, 88] |

| ISCC Hassi R’Mel (Algeria) | Parabolic trough | 25 | 130 | Reduces both natural gas consumption and CO2 emissions | Operational since 2011 | [88, 89] |

| ISCC Ain Beni Mathear Plant (Morocco) | Parabolic trough | 20 | 450 | CO2 emissions reduced by 1000 t/year. Integrated power plant and solar field achieve availability capacity factor of 93% and 95%, respectively | Operational | [88, 90] |

| Agua Prietan II (Mexico) | Parabolic trough | 12 | 464 | Expected to reduce CO2 emissions by ~391 270 t over 25 years | Under construction | [88, 91] |

| ISCC Kuraymat Plant (Egypt) | Parabolic trough | 22 | 104 | Reduces both natural gas consumption and CO2 emissions | Operational since 2011 | [88, 92] |

| Archimede (Centrale Enel Priolo Gargallo), (Italy) | Parabolic trough | 5 | 130 | Molten salt used as a HTF to supply steam at 538°C to a high-pressure steam turbine. The CO2 emissions reduced by 7300 t, as well as the amount of used gas at the plant |

Operational | [88, 93] |

Integration of CSP with natural gas can be achieved using various configurations and CSP technologies at different collection temperatures. Supplying heat to gas turbine through CSP is a technical challenge, since gas turbines operate at temperatures higher than that needed by steam turbines. On other hand, the flexible operation of open cycle gas turbine (Brayton cycle), where fuel and air can be adjusted, makes their coupling with CSP more valuable [82]. Therefore, CSP heat can be added to the cycle after compression stage and before combustion (see Figure 2b), where the adjusted fuel rate assures combustion can reach the required operating temperature. To add air steam heated in CSP directly to a Brayton cycle, pressurized receiver is the best choice to be used [83, 84]. Another configuration to integrate CSP with a gas turbine is to inject steam into the combustor, by replacing or supplementing the steam generators. This configuration is known as steam injection gas turbine (STIG), and it can increase the power output from the gas turbine, as well as increase solar share. This configuration does not require a high temperature from CSP, since the steam is injected to HRSG not to the gas combustion. Moreover, depending on the compression ratio of the gas turbine, STIG can use simple and less expensive CSP technology such as PT or linear Fresnel, with saturation steam temperature in a range of 200–300°C [85, 86]. A summary of some configurations of integrated CSP-natural gas systems is given in Table 4.

Table 4

CSP-natural gas configurations.

| Configuration | CSP heat collection temperature (°C) | CSP technology | HTF | Energy storage system | Solar-to-electricity efficiency | Ref. |

|---|---|---|---|---|---|---|

| Air heating | 800 | Solar tower | Air | Not mentioned | 37% | [94] |

| 900 | Parabolic dish | Air | Not mentioned | 38.2% | [95] | |

| 900 | Parabolic dish | Air | Not mentioned | 16.8% | [96] | |

| 1000 | Solar tower | Air | Not mentioned | 85% cogeneration | [97] | |

| HRSG injected to gas turbine | 200 | Parabolic trough | DSG | 22–26% | [98] | |

| 394 | Parabolic trough | DSG | Not mentioned | Up to 24.7% | [97] | |

| 394 | Linear Fresnel | DSG | Not mentioned | Up to 23.9% | [97] | |

| 200–280 | Parabolic trough | DSG | 4 h TES using graphite enhanced PCM of 240 degrees melting temperature and 95 kJ/kg fusion heat | 20.1% | [86] | |

| 238.1 | Parabolic trough/linear Fresnel | DSG | Not mentioned | 15–24% | [85] | |

| HRSG for cogeneration | 313 | Parabolic trough | Therminol VP1 | No storage systems were considered | 20–42% | [99] |

| 393 | Parabolic trough | Therminol VP1 | Not mentioned | 29.7% | [78] | |

| 454 | Parabolic trough | Molten salt | Not mentioned | 29.2% | [78] | |

| 454 | Linear Fresnel | DSG | Not mentioned | 26.8% | [78] | |

| 565 | Solar tower | Molten salt | Not mentioned | 27.5% | [78] | |

| 700 | Solar tower | Molten salt | Not mentioned | — | [100] |

3.3. Merits and demerits of CSP-fossil fuel

Integration of CSP with coal and natural gas provides a secure prospect to meet the renewable energy target by relying on solar energy and reducing its cost. In addition, it has a significant effect on the environment by reducing the emissions and increasing the amount of renewable energy. In fact, the CSP hybridization with fossil fuel offers economical interest with lower capital cost compared to stand-alone CSP plants [101]. This integration takes advantages of the historical availability of coal and possibility for retrofitting with existing power generation equipment, which can reduce the costs by 18% and save 25% of power generation compared to stand-alone coal plant [102]. However, the old age of the existing coal plants makes the compatibility with new solar equipment more complex and challenging. Similarly, the integration with natural gas could provide an efficient reduction of fuel and emissions and increase the energy conversion from solar energy to electricity. However, some challenges need to be addressed such as the dynamic transition, control schemes and the mismatch between the solar output and the gas turbine temperature.

Technically, the solar field could supply the required thermal energy to fossil fuel power plant through the different sections, i.e. preheating, boiling and superheating. This integration is more applicable at limited solar fraction up to 30%, and there is no need to incorporate TES as well as to oversize the solar field. Indeed, most solar hybrid power plants are not designed to include a thermal storage system to maintain the system performance at nominal conditions during off-design solar radiation periods [67].

Supplying solar steam to coal-boiler is another efficient technique to extract solar energy, when using CSP technology with temperature <400°C (i.e. PT or LFR). By integration, the steam temperature can be increased to superheat temperature by relying on coal combustion. This will increase the efficiency of steam cycle. One of the technical challenges to be considered is that when adding high percentage of solar steam to coal’s boiler, it may limit the steam generated by coal. This can cause a reduction in the heat available for superheating.

The operating temperatures of gas turbines are quite higher than that of the steam turbines, thus supplying heat from CSP to gas turbine might present serious technical challenges on the CSP end. An efficient technique is to use the collected heat by CSP to preheat the compressed air before it enters the combustion chamber. The technical challenge for this method is the ability of the combustor to achieve full fuel heating in the absence of CSP preheating. This is because the inlet temperature of air to the combustor without preheating is in the range of 300–400°C, while the inlet temperature with CSP heating can be >800°C. The main challenge for CSP-coal is the remaining lifespan of some existing power plants, which may result in an equipment age mismatch. Furthermore, retrofitting the CSP to CCGT will require a series of costly changes due to the compact design of the gas turbine.

Looking at the bright side of the CSP-fossil fuel integration it can be said that CSP-fossil fuel can provide dispatchable power and can improve sustainability by reducing the power plant’s overall CO2 emissions. Coal is available at low cost, and integration with coal will ensure the reliable and flexible operation and reduce the CSP plant costs through sharing equipment. Natural gas has low CO2 emissions compared to coal power plants and is abundant in some countries, so the majority of new constructed plants uses natural gas. Integration of CSP with natural gas could result in close to zero carbon emissions, especially with the recently developed high TES technologies used in CSP. Furthermore, and according to several previous studies, integrated CSP-fossil fuels have a high solar to electrical efficiency.

4. CSP-geothermal power plant

Geothermal energy is one of the affordable and sustainable solutions used worldwide to reduce dependence on fossil fuels and to decrease global warming. Moreover, as geothermal energy is a non-intermittent source of energy it can be used to supply base-load electricity generation. According to IEA [1], geothermal capacity is expected to grow 28%, reaching 18 GW, by 2024. Geothermal power plants (GPP) use underground heat to provide steam to the turbine for electricity generation. There are three types of GPP, as illustrated in Figure 3:

Types of geothermal power plants: (a) dry steam geothermal plant; (b) flash steam geothermal plant; (c) binary cycle.

• Dry steam GPP: where the dry steam drawn from underground wells is directed to the turbine to generate electricity.

• Flash steam GPP: where water at ~180°C temperature is drawn from the well, and converted to steam due to pressure reduction. The converted steam is separated and used for power generation.

• Binary cycle GPP: where water in the range of 107–182°C is drawn from the well to boil a working fluid in an organic Rankine cycle (ORC).

In spite of the shorter construction time and lower investment cost of GPP over other renewable energy power plants, due to the low enthalpy of geothermal resources, its overall efficiency is considered low, ~10% [103]. Thus, in order to increase the overall efficiency of GPP, the integration with other power plants can be considered. The GPP generates electricity through thermal energy as a CSP, which facilitates the integration process. Previous studies reported that, to integrate CSP with GPP, the solar energy can be directed to preheat the brine or to superheat the working fluid in the geothermal cycle, while the geothermal energy is used to preheat the feed-water in the Rankine cycle of the solar thermal power plant [104–107].

The first CSP-GPP power plant (Stillwater), located in Nevada, USA, integrates a 2 MW PT technology with a 33 MW geothermal station and a 26 MW solar PV unit [108]. The integrated CSP-GPP combines the continuous generating capacity of binary-cycle and medium-enthalpy geothermal power with solar thermodynamic technology. The heat collected by CSP is added to the geothermal brine before it enters the ORC. This increases the temperature of the incoming geothermal fluid to the plant, as well as the plant power output. Moreover, due to the CSP-GPP integration, the capacity factor of the plant is enhanced, without increasing the nominal power [88, 109].

Due to the drop in the temperature of the geo-fluid over the lifetime of GPPs, the quality of thermal-electrical conversion is reduced, which affects the plant efficiency and its power output. Ciani et al. [110] modelled an integrated CSP-GPP with and without TES and compared the monthly electrical production of both solutions. The highest electrical production was achieved in the integrated CSP-GPP with TES, where an increase of 19% in annual energy production was achieved due to the improved utilization of the extra thermal power produced by CSP and stored in TES. Zhou et al. [111] used Aspen HYSYS to simulate an integrated CSP-GPP and compared its performance with stand-alone solar and GPPs in the Australian context. The simulated CSP-GPP consisted of a geothermal power cycle of an air-cooled binary ORC, and solar heating system to superheat the working fluid (see Figure 4). The simulation results showed that the integrated CPS-GPP outperformed the individual solar power plant and geothermal plant, with a reservoir temperature of 120°C and 50 kg/s brine flow rate if 68% of the input energy was covered by solar energy. These figures drop to 49% solar fraction if the reservoir temperature is of 170°C. The study also showed that at a reservoir temperature of 150°C the cost of the electricity production could be reduced by 20% in integrated CSP-GPP, compared to the individual enhanced geothermal system.

![(a) Integrated CSP-GPP; (b) flow diagram (working fluid, 1–2; heat addition by hot brine, 2–3–4; additional heat from CSP, 4–5; power extraction through turbine, 5–6; heat rejection by air-cooled condenser, 6–1), license no. 4722461466221 [ 111].](https://oup.silverchair-cdn.com/oup/backfile/Content_public/Journal/ijlct/16/3/10.1093_ijlct_ctab034/2/m_ctab034f4.jpeg?Expires=1695368746&Signature=Z51rCSZ2KcTPzCtxbQSSGBNx02R8TE0PMKAd6Q5wgKwbxi2ermcoQ0H0053V55~1~z0LzPIfE90wxPJCRGPzOnQXc7RKC-bqbp241BAdO0-Dy4sQ9Y0w74~lnqhWQ4OY9ROmhS9y8cv3wID6jNQr-~p1wotiB3pAZFMur6HfY0E2vfAlOzUPWCMDDnVMY8gbbSvVlrpypQy1xBuVrk~ws0Govwhk5GH7EXUcXunkm7WwcipyfQh-LMz9W5nh5MCOYRF-atKhTeCMXr0ANI8Bf1mYpw-C9N4ghWfs4cUn7olv9LwaE~avRqqaHD-ltGbwPlqZr-fpev9OqMrIjX4jQQ__&Key-Pair-Id=APKAIE5G5CRDK6RD3PGA)

(a) Integrated CSP-GPP; (b) flow diagram (working fluid, 1–2; heat addition by hot brine, 2–3–4; additional heat from CSP, 4–5; power extraction through turbine, 5–6; heat rejection by air-cooled condenser, 6–1), license no. 4722461466221 [ 111].

Craig et al. [112] used IPSEpro simulation software to simulate an integrated CSP-GPP. In the simulation configuration, the geothermal energy replaced the low-temperature feed-water heaters and raised the condenser outlet temperature to ~140°C, eliminating the steam extraction from the low-pressure turbine. This configuration increased the output power for integrated CSP-GPP by 8%, compared to the individual CSP power plant. In the same study, the geothermal efficiency ratio, which represents the ratio of efficiency of integrated GPP to the efficiency of individual GPP, was used to compare GPP efficiency with and without integration. They found that the electrical efficiency conversion in the integrated CSP-GPP increased significantly from 1.7 to 2.5, and as a consequence resulted in a more efficient use of geothermal energy. Moreover, the overall efficiency of the integrated CSP-GPP was 3.6 times higher than the efficiency of the individual GPP.

Technical and economic analyses of integrated CSP-GPP using low-temperature ORC have been conducted by Ayub et al. [113]. The solar contribution to net power output was only 7%. The economic analysis for GPP (base and optimized) and integrated CSP-GPP, based on levelized cost of energy (LCOE), was performed (see Figure 5). For CSP, two operational configurations using PT were considered: (i) with a constant HTF flow and (ii) with variable HTF flow. These configurations led to a 5.5% and 6.3% improvement in the net power output, compared to the optimized GPP, respectively. The integration reduced the LCOE by 2%, while optimization of the base GPP reduced the LCOE by 8%, which was an improvement over the integration.

LCOE for GPP and integrated CSP-GPP.

Astolfi et al. [114] evaluated the potential of CSP-GPP based on ORC. The CSP was used to provide an additional heat source for the cycle as well as increasing power production. The authors performed an analysis of the integrated CSP-GPP power system under four conditions, namely, (1) high irradiance with extreme ambient temperatures, (2) good irradiance with a mild climate, (3) intermediate irradiance with high ambient temperatures and (4) low irradiance with mid-low temperatures. The obtained LCOE was 145–280 €/MWh depending on the plant’s location. It was also shown that this kind of integration could increase the overall capacity factor and guarantee safe operation for the turbine in an ORC-based plant with a reduced electricity cost.

Integration between solar and geothermal sources have been investigated for multi-generation in which the energy extracted is used for different purposes beyond electricity. Energy and exergy analyses for multi-generational integrated CSP-GPP have been carried out by Al-Ali and Dincer [115]. The analysis presented the usefulness of using multi-generation system, which results in 78% energy efficiency compared to single system with 16.4% energy efficiency. Moreover, exergy efficiency for the multi generation system was also increased from 26.2% in the single-generation system up to 36.6%. The exergy analysis also showed that solar collector is the main source of irreversibilities, with 75% of exergy destruction. Similar conclusions were reported by Ezzat and Dincer [116], in their study on the multi-generation system, powered geothermal energy and assisted by concentrated solar collectors coupled with a TES. The integrated system was used to produce hot air and hot water for industrial and residential application, as well as to produce electricity. It was shown that the overall energy efficiency of the multi-generation system was five times more than the efficiency of the base geothermal system, and the maximum exergy destruction occurred in the solar collectors.

Calise et al. [117] conducted a study using TRNSYS to simulate a highly integrated CSP-GPP system. The integrated system included ORC-PT-geothermal wells absorption, chillers-multi-effect distillation and a thermal recovery subsystem. The power generated by solar and geothermal sources was used for electricity, cooling, water heating and desalination for small communities. The exergy efficiency ranged from 40% to 50% and 16% to 20% during the thermal recovery and cooling operation, respectively, and the electrical cost varied between 0.148 and 0.172 €/kWh. The concept of multi-energy generation system, powered by integrated solar and geothermal energies, has been investigated using non-concentrating solar collector in systems with low collected temperature, <200°C [118, 119], since this technique is useful to enhance the use of the geothermal energy and overcome its low heat. Further studies on CSP-GPP are listed in Table 5.

Table 5

Integrated CSP-GPP configurations.

| Configuration/research motivation | CSP technology | HTF | CSP heat collection temperature (°C) | Energy storage system | Solar-to-electrical efficiency | Ref. |

|---|---|---|---|---|---|---|

| ORC-geothermal brine integrated with CSP | Parabolic trough | Therminol VP1 | 182°C | Not mentioned | 17.9% | [120] |

| Integrated CSP-GPP | Parabolic trough | Therminol VP1 | 290°C | Not included | 11.64% | [121] |

| Single flash integrated GPP-CSP | Parabolic trough | Therminol VP | 391°C | Not included | 16% | [122] |

| Double flash integrated GPP-CSP | Parabolic trough | Therminol VP | 391°C | Not included | 19% | [122] |

| Integrated CSP-GPP using CO2 as working fluid | Solar tower | — | 400°C–600°C | Not included | ~30% | [123] |

| Integrated CSP-GPP | Parabolic trough | Therminol VP | 391°C | Not included | 19.2% | [124] |

| Single, co- and tri –generation integrated CSP-GPP | Parabolic trough | Therminol VP | 395°C | Not included | 22% thermal | [115] |

| Micro-trigeneration plant (Integrated GPP- solar energy) | Flat-plate evacuated collector | Diathermic oil | 130°C | Diathermic oil stratified vertical storage tank | 60% thermal 6% electrical |

[119] |

4.1. Merits and demerits of CSP-GPP

CSP and GPP both generate electricity using carbon-free thermal energy. Fortunately, many locations have both energy resources that make this hybridization option more viable. In addition, the good synergy between CSP and GPP could result in significant savings of capital cost and land use due to shared equipment and space. Moreover, the integration of CSP systems can increase the temperature and efficiency of GPP by raising the turbine inlet temperature. Integrated CSP-GPP can supply dispatchable power and cover peak demand with zero carbon emissions. However, the heat from geothermal was considered as a low-level grade; this should be taken into consideration, when both resources integrated for electricity production. In the absence of solar radiation, the capacity factor of the system will be low, which can affect the grid stability [120]; thus, incorporating TES into the system can maintain the stability, but with an additional expenses in the capital expenditures. In practice, only few CSP-GPP hybrid plants are implemented for power production. This can be explained by the high initial, operation and maintenance costs as well as the complexity of building the entire hybrid power plant.

One of the efficient but challenging techniques for integrating low grade heat CSP-GPP is the multi-generation system. This might increase the utilization of solar and geothermal resources for multi-purpose, as well as reduce the wasted energy. As a result, a significant increase in the efficiency in the efficiency of integrated CSP-GPP compared to that of single generation can occur. Moreover, the exergy efficiency of single system will be less than about of the multi-generation. On the other hand, 75% of exergy destruction occurs in the solar field. On top of that, the use of multi-energy system powered by CSP and GPP comes with other advantages as better sustainability, environmental performance, better system efficiency and better cost-effectiveness.

5. CSP and biomass

Biomass energy is a well-established technology; there are several power plants worldwide, which utilize different biomass fuels, mainly from agricultural residues, animal waste, plants and other waste. Biomass can be converted into electric power by (i) producing thermal heat by direct combustion and (ii) producing the fuel needed for combustion by thermochemical or biochemical conversion (see Figure 6). The integration of solar and biomass energy to generate power is recommended in the areas where these two resources are abundant. Many countries have abundant solar and biomass resources. For instance, in Bangladesh, insolation varies from 3.8 kWh/m2/day to 6.4 kWh/m2/day, with an average of 5 kWh/m2/day. In addition, Bangladesh is an agricultural country and produces large amounts of biomass (agriculture residues, wood, animal waste and other waste) [125]. India has DNI of ~4–7 kWh/m2/day and produces 370 million tons of biomass every year [126]. In southern Spain, southern Portugal, southern Italy, southern Greece and southern Turkey, the DNI varies between 1600 and 2000 kWh/m2/year; the main suppliers of biomass in Europe are Germany, France, Spain and Poland, both directly and indirectly from agriculture [127–129]. The combination of CSP-BIM energy shows good potential to deliver 100% clean energy [130]. Both CSP and biomass technologies convert thermal energy to electrical power and that makes them compatible for integration; different components can be shared during this integration, lowering the investment cost [131].

Biomass to electricity conversion methods.

Borges thermo-solar plant, located in Spain, was the first commercial integrated CSP-BIM plant in the world and has operated since December 2012. The electricity production is 98 000 MWh/year generated by PT during the day and by biomass energy at night, with a 22.5 MW net power capacity, avoiding 24 500 tons emissions [132, 133]. Servet et al. [134] evaluated the integrated CSP-BIM power plant compared to the stand-alone CSP and biomass power plant. The study showed that, due to the possibility of using shared equipment, the investment cost was ~24% lower than that related to the two technologies, resulting in lower LCOE for the integrated system. Moreover, energy generation was 2.77 times higher than the individual CSP plant, and the use of biomass technology eliminated the need for TES. Finally, the integration of CSP with biomass energy led to 100% use of renewable energy.

Integration of CSP-BIM systems has been investigated in several studies using different CSP technologies. Kaushika et al. [135] described the integration of PT and a biomass plant using the biogas produced from the waste of the distillery plant. Two studies, [136, 137], investigated the integration of PT and biomass energy in order to (i) supply heat to ORC through a biomass furnace and PT, (ii) to superheat steam generated by PT and (iii) to use steam from PT for biomass gasification. The solar collection temperature ranged from 305–993°C and the overall efficiency was in the range of 16%–17.8%. The conversion efficiency from solar to electrical recorded an increase of 10.5%, while the investment cost decreased by ~23.5% due to the integration [138, 139]. Multi-generation systems to produce electricity, chilled and hot water by integrated PT and biomass have also been investigated. The results showed high overall efficiency and electrical efficiency at ~77.4% and 17.8%, respectively, [140–142]. The integration of LFR with biomass energy has been investigated; this integration allows to increase the steam temperature up to ~500°C, leading to higher conversion efficiency [143, 144] and [145].

Nixon et al. [146] evaluated the technical and economic feasibility of integrating LFR with a biomass power plant for multi-generation based on five case studies, with thermal capacities ranging from 2.0 to 10 MW. The results showed that the integrated CSP-BIM power plant can be a viable option for multi-generation (electrical power, cooling and heating) for small and medium applications, saving up to 29% biomass and land, with 8.3–24.8 $/GJ and 1.8–5.2 ¢/kWh increase in cost per exergy loss and LCOE, respectively. Peterseim et al. [147] investigated a number of integrated CSP-BIM systems to determine the best technical and economic combination. The steam was generated by the biomass boiler and the CSP supplied additional steam during the daytime. According to the study, the solar tower with DSG was the best combination in terms of net efficiency ~33.9% and environmental impact. In addition, the best economic combination was LFR with DSG with an investment cost AU$ 4.5 m/MWe. The integrated CSP-BIM delivered ~69% lower annual electricity generation than individual CSP systems [147].

Peterseim et al. [148] investigated the integration of a solar tower with biomass in Griffith, New South Wales, to generate steam at high temperature 525°C and 120 bar using a case study of total capacity 30MWe, 15MWe biomass, and 15MWe CSP with 3 hours TES. The results showed that the integrated system provided lower electricity cost at AU$155/MWh, as well as reduced the investment cost by 43% compared to stand-alone CSP systems. The solar tower has the potential to provide steam at high temperature and pressure, >500°C and 100 bar, which is considered identical to the biomass plant [149]. With a solar collection temperature ~1500°C, an energy efficiency up to 56% was recorded for the solar tower and biomass multi-generation system to produce both methanol and electric power [150, 151]. This encouraged further researchers to investigate the technical and economic potential of the integrated solar tower and biomass energy [152–154].

Using CSP for gasification of biomass is one of the research topics investigated in several studies. A high temperature, over 1000 K, is required for gasification; therefore, gasification of biomass requires a heat source. Using heat from CSP for gasification showed the potential benefits of using solar thermal energy in terms of high quality of syngas composition (higher H2/CO

ratio) and less contamination with CO2

[155]. Although gasification is commonly performed at high temperature, some attempts have been made to operate the process at low temperatures. Ravaghi-Ardebili et al. [156] modeled a biomass gasification unit using low temperature of 410°C collected by PT. In order to achieve efficiency equivalent to the efficiency of high-temperature biomass gasification, different operating conditions and parameters, along with the alternative design option in the reactor configuration were considered. Khalid et al. [157] evaluated the energy and exergy efficiencies for a hybrid solar tower and biomass integrated system to generate multi-energy for commodities heating, cooling and electrical power (Figure 7). Energy and exergy efficiencies of the integrated system were 66.5% and 39.7%, respectively, whereas, energy and exergy efficiencies for the individual systems were 64.5% and 37.6% for biomass, and 27.3% and 44.3% for solar tower. Although the study showed that the thermal efficiency of the multi-generation integrated system was higher than the efficiency of a single system, the exergy efficiency for the solar tower alone was higher than that of the integrated system. Similar to the integration of geothermal and solar energy, the exergy analysis showed that the solar collector is the main source of irreversibility. Additional studies are summarized in Table 6.

Table 6

Integrated CSP-BIM configurations.

| Configuration/research motivation | CSP technology | HTF | CSP heat collection temperature (°C) | Energy storage system | Solar-to-electrical efficiency | Ref. |

|---|---|---|---|---|---|---|

| Increase CSP efficiency through integration with biomass | Parabolic trough | Thermal oil | 393°C | 7.5 h molten salt TES | 27% | [158] |

| Integrated CSP-BIM for DSG | Parabolic trough | Thermal oil | 350°C | Not included | — | [159] |

| Integrated CSP-BIM for DSG | Solar tower | Molten salt | 540°C | 3 h molten salt TES | — | [148] |

| Integrated CSP-BIM for gasification | Solar tower | Air | 877°C | Not considered | 17.7% | [160] |

| Integrated CSP-BIM | Solar tower | Air | 700°C | 2 h storage | 11% | [161] |

| Integrated solar and biomass for power production | Solar tower | Molten salt | 500°C | Not considered | — | [162] |

5.1. Merits and demerits of CSP-BIM

Integration of solar energy and biomass has showed good synergy; CSP and BIM both generate electricity using thermal energy, with a potential to deliver 100% dispatchable power supply. CSP can be integrated with biomass to produce electricity or biofuels, also integration can be used for multi-energy generation. The integration of the CSP-biomass can improve the flexibility and competitiveness of the power plant, increasing the capacity factor of the plant, as well as decreasing the size of the solar field of the equivalent stand-alone CSP plant. Moreover, other elements, such as the turbine generator, compressed air, condenser, cooling tower, deaerator pipes, feed water, valves, control devices and many other components, can be shared, which results in lower investment cost. In addition, the biomass consumption in the hybrid power plant is reduced compared to the stand-alone biomass plant and thus, the risk associated with the biomass supply is decreased [163].

Solar thermal energy can be injected at different points and temperatures to obtain optimal steam parameters for the host plant in terms of temperature and pressure. Under such conditions, some CSP technologies could be favored than others. For instance, for steam requirements of T > 500°C and P > 100 bar, solar tower technology is more appropriate which can be used for direct steam generation without TES or molten salt with TES. Furthermore, CSP-biomass hybridization offers the possibility to operate on new thermodynamic cycles other than the classical solar ORC such as Brayton cycle, supercritical CO2 cycle and combined ORC-externally fired gas turbine cycle for both power generation and cogeneration applications [152, 164].

CSP can be used as a clean source of heat, to produce biofuels via gasification. The fuel produced this way is considered as a renewable energy carrier. Gasification of biomass through CSP can achieve up to 50% solar-to-chemical efficiency. However, the gasification process requires high temperature; therefore, using low temperature relevant to solar-thermal technologies for gasification is a challenging process and needs more efforts to be accommodated. Actually, one of the main disadvantages of integrated CSP-BIM is related to the highly technical operation and temperature limits.

6. CSP-photovoltaic

The integration of PV systems with CSP can reduce energy production costs and offer a dispatchable power solution. PV-CSP hybrid systems can be of two ways: (i) decoupled PV-CSP in which both PV and CSP subsystems can be planned independently and integrated by the electric power system [160] and (ii) coupled systems such as PV-topping technology or the spectral beam splitting (SBS) technology. In decoupled PV-CSP systems, PV panels may contribute to power production during the day as PV has lower LCOE, while the CSP plant with TES can provide the necessary power during low irradiance periods supplementing PV or operating during the night [165]. The idea behind PV-topping system is to recover the heat dissipated from solar cells; here cells are operated at a high temperature and the dissipated heat is used to generate solar power through the CSP system [166]. SBS technology is based on the fact that PV cells use visible and near infrared radiation, thus the other part of the incident radiation can be separated and used in the receiver of a CSP plant [167]. While decoupled systems have begun their commercialization stage, coupled ones are still under research and face several technological challenges. This is the reason why in this section, only a review of decoupled systems is performed.

Although both PV and CSP use the same energy source, the inclusion of a storage option in the CSP allows for the continuous operation of the power plant, regardless of the solar energy availability. Therefore, such integration can offer better stability in terms of electrical power supply during both day and night. In addition, the integration of PV with the CSP plant presents an economic benefit as the levelized cost of electricity of the PV technology is lower than that of CSP [168]. This integration might lead to a lower cost solution, compared to CSP alone, especially in terms of baseload output requirements.

A hybrid CSP-PV plant consists of a field of PV modules together with a CSP field, coupled with a thermodynamic cycle, usually the ORC. The CSP part of the hybrid plant can be coupled with a thermal storage facility, to improve the dispatchability and renewable penetration in the grid. The schematic diagram of a typical CSP-PV plant is shown in Figure 8, where two different sections (CSP and PV plants) are connected to the load [160]. One of the main challenges in this integration option is the optimization of the dispatch strategy to fulfil certain load objectives.

Recent studies have proven that hybridization of CSP-PV can provide dispatchable and stable power at lower production cost. Most of these studies are focused on the techno-economic evaluation of this integration option to reduce the LCOE and improve the capacity factor for baseload power. These advantages have attracted various CSP-PV projects as shown in Table 7. On other hand, many authors have carried out numerical simulations and economic optimization, on various configurations for planned or existing projects, including thermal energy and batteries storage. Selected recent studies on CSP-PV integration are summarized in Table 8.

Table 7

Summary of worldwide CSP-PV power plants.

| Project | CSP technology | CSP capacity (MW) | PV capacity (MW) | Energy storage | Status | Ref. |

|---|---|---|---|---|---|---|

| Atacama I (Chile) | Solar tower | 110 MW | 100 MW | 17.5 h molten salt | Under construction (expected to be operational by May 2020) | [170, 171] |

| Redstone and Lesedi and Jasper (South Africa) | Solar tower | 100 MW | 75 + 96 MW | 12 h molten salt | Under construction (commercial operational date Q1, 2022) | [172, 173] |

| Atacama II (Chile) | Solar tower | 110 MW | 100 MW | 15 h molten salt | Under development | [174] |

| Copiapó (Chile) | Solar tower | 260 MW | 150 MW | 14 h molten salt | Under development | [175] |

| Noor Midelt I Phase I (Morocco) | Parabolic trough | 190 MW | Up to 210 MW | 5 h molten salt | Under construction (delivery of the first electricity to the grid is planned from 2022) | [176–178] |

| Noor Midelt II Phase II (Morocco) | Parabolic trough | 190 MW | Up to 210 MW | 5 h molten salt | Under construction | [176, 177] |

| Ottana power plant (Italy) | Linear Fresnel | 630 kW | 400 kW | 15 MWh thermal oil | Operational since 2017 | [179] |

| Noor Energy I (Dubai) | Solar tower and parabolic trough | 700 MW | 250 MW | 15 hours molten salt | Under development | [180] |

Table 8

Summary of recent CSP-PV studies.

| Capacity | CSP technology | HTF | CSP heat collection temperature (°C) | Efficiency/efficacy | Remarks | Ref. |

|---|---|---|---|---|---|---|

| 100 MW for CSP and 60 MW for PV | Solar tower | Molten salt | — | Capacity factor: 90% | Hybrid CSP-PV plants can achieve capacity factor over 90% for base load when dispatching the use of the thermal storage system. A fixed tilt PV system optimized in winter is the favorable configuration | [181] |

| 20 MW of PV and 30 MW of PTC with 15 h TES | Parabolic trough | Molten salt | — | LCOE varies from 15.69 to 8.57 USD/kWh from 2014 and 2050 | The integration of CSP-PV is a reliable and clean option for mining industries in Chile and can supply 24 h continuous electricity | [182] |

| 400 kWe of PV and 600 kWe of CSP with 15 h TES | Linear Fresnel | Thermal oil | 260°C | Concentrated PV efficiency of 19.9% and ORC average efficiency of 18.5% | The fully integrated control strategy gives better annual performance and power production | [183] |

| 400 kW of PV and 600 kW of CSP | Linear Fresnel | Thermal oil | 260°C | Nominal PV efficiency 14.9% and nominal ORC efficiency of 19% | Hybridization is recommended for long load durations (>16 h) Large sizes and higher costs are needed for the low irradiance site |

[169] |

| 73 kW for PV and 30 kW for CSP | Parabolic trough | Water | 116°C | Cycle efficiency 10% | For a load of <60 kW, the LCOE of the hybrid CSP-PV is 2% greater than the PV-battery. For load exceeding 500 kW, it is 26% lower | [184] |

| 20 MW for PV and 19.9 MW for CSP | Solar tower | Molten salt | 565°C | Capacity factor 74% | The annual output of the hybrid plant increases with the TES capacity. In the constant output dispatch strategy, the LCOE decreased by 19% compared to the conventional system | [185] |

| 50 kW for PV and 50 kW for CSP | Parabolic trough | Glycerol | 275°C | Design cycle efficiency 20.26% | The LCOE for the hybrid system is ~0.19 USD/kWh and ~0.26 USD/kWh for PV system for the same capacity utilization factor of 0.56 | [186] |

| 100 MW for PV and 110 MW for CSP | Solar tower | Molten salt | — | Power block efficiency of 37% and PV panel efficiency of 18% | Hybridization can reduce the LCOE by 5.6% and the loss of power by 90%. The techno-economic performance of the hybrid plant can be improved using an optimized design | [170] |

6.1. Merits and demerits of CSP-PV

According to the literature review, the hybrid CSP-PV option has significant potential for coupling the technical and economic advantages from both technologies. In fact, such option may contribute to improve the power quality, grid stability and renewable penetration in the grid compared to PV plant alone. Moreover, both PV and CSP technologies have reached their maturity, which make their integration more attractive and cost effective. This hybridization is suitable for large-scale solar power plants but can also be implemented in micro-scale solar power plants in remote areas. With the low cost of PV technology, the CSP-PV hybridization can replace the complex and costly electrochemical battery with a lower cost and well-established thermal storage system. Such configuration could achieve a minimum of LCOE of 0.12 USD/kWh.

Several large CSP-PV hybrid plants are in the planning and execution stages. In order to improve the technical and economic capabilities, it is recommended that the contributions of CSP and PV power in an integrated management strategy are optimized to maintain a constant power supply. In addition, the dispatchability of both systems could be improved with longer load durations and better irradiance levels.

Another possibility to increase the overall efficiency is the compact CSP-PV hybrid system, which recovers the waste heat and/or the unwanted solar radiation from the PV technology to be used for the CSP system; however, this option is still not developed in commercial projects [187].

7. CSP-wind energy

Wind farms have the capability to supply >20% of the world’s electricity at a low operational cost [188]. However, the fluctuation of wind speeds results in energy fluctuations and intermittent supply; therefore, energy storage and/or the use of a hybrid system is recommended [189]. The option of using a storage system for a wind farm is not an effective option in terms of cost, but by integrating CSP with WE there is the potential for the use of commercial TES, using molten salts, which might ensure a continuous supply and better stability to the grid.

The production of solar and wind energies depends on variable meteorological features of solar radiation and wind speed. Consequently, it is difficult to predict their actual production profiles. Their output is injected to the grid as an instantaneous reaction to match supply and demand [190]. To conduct an effective integration between CSP and wind, their electricity production profiles should be complemented as much as possible to minimize the need of additional capacity.

The integration of both technologies worldwide has been study by different researchers. Monforti et al. [190] developed a modeling approach to estimate the production of wind and solar energy, as complementary resources in the same geographical location in Italy. The model results showed that the production of the two sources have complementary time behavior that support their integration in the energy system. Slusarewicz and Cohan [191] collected solar and wind data and modeled the solar and wind output to investigate their complementarity in different locations in Texas. They selected five wind sites and seven solar sites. They separated wind sites with respect to magnitudes and pattern diurnally and seasonal of wind speed, into coastal and noncoastal sites located at south and west Texas, respectively. The results revealed that over the year, solar production is complementary with wind in both costal and noncoastal sites. Therefore, integrating solar and wind resources can produce reliable power production on an annual basis. Agelidis and Shrivastava [192] analysed the correlation between solar and wind resource availability for a coastal location in Australia; they also studied the grid electricity load demand. According to their results, they reported that integration of solar and wind resources in Australia is very promising to supply base loads.

The possibility of integrating wind and solar power in the northeastern part of Saudi Arabia was investigated by Sahin [193], studying the correlation between wind speed and solar radiation. The results demonstrated that a maximum average solar power of 328 W/m2 occurred in summer when the wind power is a minimum of ~80 W/m2; the minimum solar power of 98 W/m2 occurred in winter when the wind power was a maximum of 233 W/m2. Such results indicated that peak solar and wind powers are not possible simultaneously, and thus the integration of solar and wind power can result in less variation through the year.

Many studies directed for matching power generated by wind energy with the utility electrical loading, by incorporating CSP technology. Reichling and Kulacki [194] studied the thermo-economic performance of the integration of wind and PT in Minnesota. Their results showed that an integrated CSP-WE system not only improved the electrical load compared to standalone wind technology but also a higher generating capacity was obtained. Other studies [8, 195, 196] revealed that combining CSP plants with wind farms can improve the electrical load matching conducted. Vick and Moss [195] compared the electrical generation from renewable energy systems (i.e. actual wind farm data along with predicted PT output with and without TES) and utility load in California and Texas. They found that despite the fact that hybrid wind-CSP system was more expensive than a standalone wind farm, the integration offered better electrical load matching to meet the peak demand and matching optimized with the inclusion of 6 hours storage system.

Santos et al. [197] evaluated the advantage of the combination of wind and solar power on the stability of baseload in the region of Andalusia in Spain, taking into consideration the availability of solar and wind energy resources and the storage system capabilities for CSP. They aimed to determine optimal locations for wind farms and CSP plants, based on spatiotemporal balancing between the wind and solar capacity factor, then analysed the stability of combined power production. The location that provided the highest capacity factor during daytime was selected, as well as the location that provides the highest capacity factor during the night time for the wind farm. There was a reduction in power fluctuation, during the daytime by one-third due to combined CSP and wind energy. Moreover, the study showed an increase in annual power production due to the seasonal balance between the CSP plant and wind farm.

Aliyu et al. [198] demonstrated that the integration of wind turbines and solar thermal power plants through a central electric heating system could address the intermittency of wind and solar energy. The proposed system converts wind energy to thermal energy using the electrical heating system, which has high-energy conversion efficiency and is compatible with any type of CSP technology. The system had three operation modes: normal mode, where power was supplied from wind and/or CSP in the form of thermal energy to thermal storage; standby mode, when wind power is insufficient, and power supplied by CSP to the steam turbine and/or thermal storage; and finally, the stop mode, when the thermal units are not working, and wind power output was directly connected to the grid. A similar system, which integrates a wind farm, a CSP plant and an electric heater, was studied by Yang et al. [199]. The annual simulation of the plant showed the effectiveness of the proposed system for reducing the deviation from the generating plant. Petrakopoulouet al. [200] studied the potential for meeting the energy demand for the Greek island Skyros using a hybrid wind-CSP power plant that included energy storage systems with 48% of the required power supplied from CSP. Okazaki et al. [201] studied the feasibility of converting wind energy at the wind turbine tower to thermal energy on demand, which then transferred to the utility by the circulation of HTF, and stored in the thermal storage tanks (Figure 9). This study is unique in the sense that there was integration between wind and CSP technology at the components level, in contrast to other studies, which focus on hybridization at the grid. The conversion of wind energy to thermal energy was found to be more economical than wind with battery energy storage [201, 202]. Another study conducted by Young et al [203] proposed integration between wind farm, CSP with TES and electric heater to reduce wind limitation and improve scheduling flexibility. The electric heater used to convert excess wind power to thermal heat which can be stored in TES of CSP.

Ayadi et al. [204] conducted an economic assessment of an integrated wind farm and CSP with TES in terms of final yield and capacity factor. The study showed a significant increase in the capacity factor ~67% for the integrated system compared to the standalone wind plant and a ~32% increase in the integrated system when compared to the standalone CSP with TES. However, the LCOE of the integrated system increased by 64%, compared to the standalone wind farm and decreased by 28% compared to the CSP plant with TES. The results obtained by Ayadi and Alsalhen [204] indicated that the integration of wind and CSP leads to a more stable power supply. Chen et al. [205] analysed the critical success factors for integrated solar and wind power generation plants and then adopted those factors in a real case study in selecting the best solar wind power generation project. Further studies on the integration of wind energy and CSP are summarized in Table 9.

Table 9

Integrated CSP-WE systems.

| Configuration/ research motivation | CSP technology | Collection fluid | CSP heat collection temperature(°C) | Storage system | Solar to electrical efficiency | Ref. |

|---|---|---|---|---|---|---|

| Integration of 67 MW wind farm with 33 MW CSP with TES | Parabolic trough | Therminol VP1 | 400°C | 6 h molten salt TES | 16% (annual) | [195] |

| Investigate the value of integrated wind and solar resources for in Canada | Any type of CSP | Depends on CSP type | Depends on CSP type | Not mentioned | — | [206] |

| Wind farm/CSP with TES in Skyros island | Parabolic trough | Therminol VP1 | 380°C | 14 h molten salt | 22.9% (annual) | [200] |

| Integrated CSP-WE | Parabolic trough | — | — | Not mentioned | 14% | [194] |

| Integrated CSP-WE-Geothermal | Parabolic trough | Therminol VP1 | 350°C | Not mentioned | Overall efficiency 36.7% | [14] |

7.1. Merits and demerits of CSP-WE

From the literature review, the integration of CSP and wind farms can be achieved either at the grid or component level, as illustrated in Figure 10. The integration at the grid level can be more feasible in locations that have maximum average solar power in summer with minimum wind energy, and minimum solar power in winter with maximum wind energy to cover the required load. At grid-level integration, the benefits result from the TES rather than components of the CSP. The thermal storage presents a cheaper and more stable storage solution for the output power compared to batteries especially for big capacity and small solar multiple [207].

Energy flow diagram for integrated CSP-WE.

The integration at the component level can be achieved after converting wind energy to thermal energy. This can be done either at the wind tower, where the wind turbine acts as the CSP tower or by integrating the CSP with the wind farm through an electrical heating system. The integrated CSP-WE plant can meet peak demand, reduce power fluctuation and provide electrical power at a high capacity factor from renewable energy sources. However, this system is considered as a weak synergy, as there is no integration at the component level, which would elevate costs and land requirements compared to the standalone wind farm or standalone CSP plant.

Both wind and solar energy are variable renewable energy (VRE), and they pose different challenges to grids. Those challenges include the following:

➜ The actual power production profiles of solar and wind energy cannot be exactly predicted because they depend on variable meteorological data. Therefore, to conduct an effective integration between the two technologies, the electricity production profiles for both of them should be complemented as much as possible.

➜ Variability and uncertainty; the grid operators cannot control energy produced by VRE; they only accommodate it when it is available. Therefore, the grid operator requires some agility to keep extra standby running when needed.

➜ Location; most of the suitable locations with strong solar radiation and wind lack the necessary transmission infrastructure needed for power supply.

➜ The availability of accurate wind data along with the solar availability in the selected location. This is very important to assess the economic feasibility of the integrated system.

8. Limitations, challenges and recommendations for CSP integration

Concentrating solar power and each of the other power plant sources are lying at different points of the technological spectrum. Consequently, integration of CSP with other sources will certainly reveal different technical, financial and even political issues. Therefore, the concept of CSP integration already existed but its implementation is considered somewhat limited. This section presents various obstacles and challenges that hinder development of CSP integration with different energy resources, along with some recommendations whenever possible.

• The lack of reliable biomass, geothermal and wind data with the solar availability in specific locations are one of the main obstacles for the acceptance and further deployment of hybrid systems of renewable energy sources.

• Most of the existing and new major economies rely on fossil fuel, especially coal, in spite of the availability of the renewable energy sources. Therefore, a political and economic framework is an important factor, as it controlled the promotion of CSP because of their currently higher LCOE, compared to fossil fired power plants and some other competitors.

• CSP needs at least 2000 kWh/m2 of sunlight radiation annually, as the threshold from which an economic operation of CSP plants is possible; this clearly limits the appropriate location for this technology.

• CSP requires land resource up to thousands of hectares with certain criteria in terms of topography and shading. Thus, for hybridization, a suitable area should be available for integrated power plants.

• Arid and desert locations are more suitable to CSP from a DNI perspective, whereas conventional power plants are usually located near a location with high water resources for cooling purposes. This also can limit the chance of CSP–conventional power plant integration.

• An appropriate infrastructure is needed for solar power plants for accessing roads, high or medium voltage power grids and water resources if wet cooling is planned. Additionally, pipelines should be favourable for water transport or fuel transport for hybrid plant operation.

• Most of the integration between CSP and fossil fuel is applied by retrofitting the ageing plants as opposed to new build plants, which limits the solar share in the integrated CSP-fossil fuel plant.

• One of the challenges is to integrate CSP with newly built fossil fuel plants at the design stage, with the aim to provide a highly efficient plant and better economics.